MARK OUT ASS.- PART 2. - PRACTICAL GUAGE USE

NAME: Total marks 15 Mark:

Job HT 1 Feeler Gauging

Use a set of feeler gauges to measure the maximum and minimum gap between the nuts on the six test pieces your teacher will give you.

| Sample |

Minimum Gap |

Maximum Gap |

| A |

||

| B |

||

| C |

||

| D |

||

| E |

||

| F |

||

| G |

Job HT 2 Radius Gauging

Use metric and imperial radius gauges to measure the concave and convex radii on the test piece supplied by your teacher.

| Radius |

Actual Size Of Radius |

| A |

|

| B |

|

| C |

|

| D |

|

| E |

|

| F |

Job HT 3 Screw Pitch Gauging

Using metric and imperial screw pitch gauges outside callipers and rule, find the pitch and outside diameter of the six sample screw threads supplied by your teacher.

| Sample |

Diameter |

Pitch (TPI or mm) |

| A |

||

| B |

||

| C |

||

| D |

||

| E |

||

| F |

Job HT 4 Form Gauging

Using a screw cutting tool thread gauge having both 55° and 60° angles, check the four cutting tool samples provided by your teacher and complete the chart by placing the number of the sample next to the correct description.

| Sample No |

Description |

| Exactly 55° |

|

| Exactly 60° |

|

| Just less than 55° |

|

| 60° but having one convex cutting edge |

Job HT 5 Thickness Gauging

Use a thickness gauge to measure the thickness of six sample pieces of sheet metal supplied by your teacher.

| Sample |

Thickness |

| A |

|

| B |

|

| C |

|

| D |

|

| E |

|

| F |

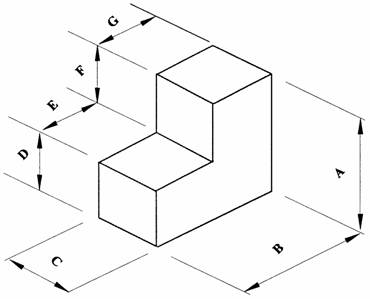

JoB HT 6 Rule Measurements

Use a 150 mm rule to measure the seven dimensions to the nearest 0.5 mm on the stepped block.

| Letter |

Rule Size |

| A |

|

| B |

|

| C |

|

| D |

|

| E |

|

| F |

|

| G |