ROUTINE DECK MAINTENANCE

(Ranger Hope © 2022, contains images courtesy of A.N.T.A. publications)

Planned

Maintenance

Survey Requirements

Corrosion and Deterioration

Preservation of Structures

Glues

and Sealants

Working with Confined spaces

Marine Pollution

Planned Maintenance

The Master is responsible for the seaworthiness of the vessel and must ensure that all national and international requirements regarding safety and pollution prevention are being complied with. Effective planning is required to ensure that the vessel, its machinery systems and its services are functioning correctly and being properly maintained, including dry-docking to maintain hull smoothness.

Planned maintenance is primarily concerned with reducing breakdowns and the associated costs. Planned maintenance is of two kinds:

Preventative maintenance is aimed at preventing failures or discovering a failure at an early stage.

Corrective maintenance is aimed at repairing failures that were expected, but were not prevented because they were not critical for safety or economy.

Advantages of Planned Maintenance

Fewer breakdowns and repairs.

Equipment operates efficiently at all times.

Fewer hazards to the crew when working with well maintained equipment.

Vessel complies with survey requirements at all times.

No areas of the vessel or items of equipment are overlooked or neglected.

Elements of a Planned Maintenance Program

You can develop a basic maintenance program for your vessel by taking the following steps:

Step 1 Determine what items need to be maintained.

Step 2 Determine the type of maintenance tasks required on each item.

Step 3 Determine the frequency of carrying out particular maintenance jobs.

Step 4 Prepare a maintenance schedule.

Step 5 Develop operational and recording procedures.

You will need to consider the following issues in the planning process

Is an item worth maintaining? What would be the real cost of failure to maintain that item?

Equipment manufacturers instructions.

Statutory survey requirements.

Classification society requirements.

Maximum length of survey cycle.

Magnitude of maintenance task.

Maintenance/inspection that can only be carried out when the vessel is out of water.

Resources required.

Recording.

Length of voyages, routes and trades the vessel is involved in.

Spare parts replacement.

The plan must be adaptable to various weather conditions and must be flexible enough to accommodate changes in vessel’s trade.

It is convenient to draw up a maintenance schedule by breaking down the plan into various ‘time phases’. Two suggested categories are:

Short-term maintenance.

Long-term maintenance.

Short-term maintenance may include weekly, fortnightly or monthly inspections and greasing routines. Long term maintenance will involve major overhauls and surveys. Remember too that some operational maintenance tasks will only be carried out as and when necessary.

The actual operation and documentation of the plan will vary from vessel to vessel. Many vessels use a card index system or computer program for this purpose. Usually, a job sheet is prepared for each job. The job sheet contains a description of the work and a list of relevant spare parts and references to drawings and instruction manuals. On completion of the job, relevant details are entered in the job sheet.

Maintenance and Survey Requirements

It is obvious that for a vessel to float, water must be prevented from gaining entry into the hull. The vessel designer has to ensure that under normal use water will not enter the hull in sufficient quantities to sink it. The shipbuilder ensures that is of sound construction to meet these requirements. This is verified at the initial survey carried out by an Authority.

It is your responsibility to ensure that your vessel’s watertight and weather tight integrity is maintained throughout it’s period of service. This is ensured by periodic surveys carried out by the Authorities. In general terms, the survey requirements require the vessel to be watertight below the freeboard deck and weathertight above the freeboard deck. This means that the shell plating must be intact and the closures to all openings leading to the hull should be in efficient working order. No alterations should be done to any structure that would adversely affect the watertight integrity of the hull without the approval of the appropriate survey authority.

It is essential that you are thoroughly familiar with the locations and closing mechanisms of all openings on your vessel through which water may enter the hull. This way you will not neglect to maintain, test and check the efficiency of any of the closing arrangements.

Maintenance Items

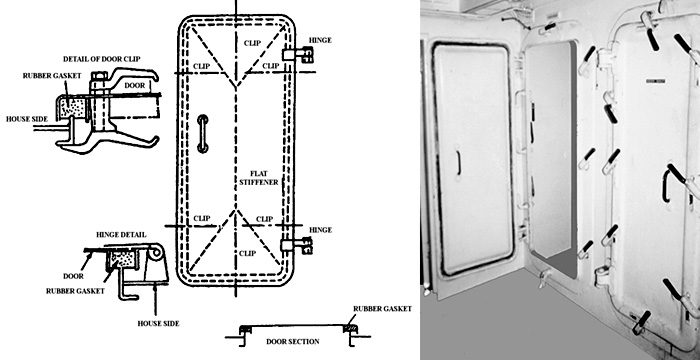

Check that all access openings at ends of enclosed structures are in good condition. All door clips, clamps, and hinges should be free and well greased. All gaskets and watertight seals should be crack free. Ensure that the doors open from both sides. Figure 1.25 shows the typical components of a weathertight door.

Figure 1 Weathertight door on Main deck

Check all cargo hatches and access to holds for weathertightness.

Seals should never be painted.

Regularly inspect all machinery space openings on exposed decks.

Check that any manholes and flush scuttles are capable of being made water-tight.

Check that all ventilator openings are provided with efficient weathertight closing appliances and repair any defects.

All air pipes of diameter exceeding 30mm bore, must be provided with permanently attached satisfactory means for closing the openings.

Ensure that the non-return valves on overboard discharges are operating in a satisfactory manner.

Check that all freeing ports are in a satisfactory condition, e.g. shutters are not jammed, hinges are free and that pins are of non corroding material. Check that any securing appliances, if fitted, work correctly.

Tests

You can test the efficiency of closures by means of a simple “hose test” or by a “chalk test”.

Survey Requirements

Definitions

Survey a thorough examination performed by, or in the presence of a surveyor or an authorised person or society.

Inspection a visual inspection performed by an approved person.

The Certificate of Survey is issued on completion of an Initial Survey. The surveyor submits a report, detailing the condition of the hull, machinery and equipment, and makes a written declaration of such condition.

Initial Survey

The main purpose of this survey is to ensure that the vessel will be able to perform the tasks for which it is intended.

All aspects of the vessel’s construction are examined to ensure that it meets the requirements of the National Standards for Commercial Vessels from AMSA. After the construction is complete, the Authority surveys the vessel once more and if satisfied, issues the operator with a "Certificate of Operation" and the vessel with a “Certificate of Survey”.

Both or their evidence (plasticized document or metal plate) should be displayed near the steering position, except on passenger vessels, where the evidence should be displayed in such a position that it is readily visible to passengers, or if the Authority requires, and in a position on board that it shall be visible from outside the vessel.

Periodic Surveys and Inspections

All vessels must under go 'Periodic Surveys and Inspections' to satisfy the Authority that the vessel continues to comply with all its laws and regulations.

Typical Annual Surveys

Equipment.

Running trial of each main engine and associated gearbox.

Operational test of bilge pumps, bilge alarms and bilge valves

Operation test of all valves in the fire main system.

Operational test of all sea injection and overboard discharge valves and cocks.

Operational test of main and emergency means of steering.

Running trial of all machinery essential to the safe operation of the vessel.

Inspection of all pipe arrangements.

General examination of machinery installation and electrical installation.

All safety and relief valves associated with the safe operation of the vessel to be set at the required working pressure.

Pressure vessels, and associated mountings used for the generation of steam under pressure or the heating of water to a temperature exceeding 99 degrees Celsius

Inspection of the liquefied petroleum gas installation.

Inspection of cargo handling, fishing and trawling gear.

Inspection of escapes from engine room and accommodation spaces.

Inspection of personnel protection arrangements in machinery spaces.

Inspection of casings, superstructures, skylights, hatchways, companionways, bulwarks and guard rails, ventilators and air pipes, together with all closing devices.

Inspection of ground tackle (anchors and chains).

Two Yearly Surveys

Hull externally and internally except in way of tanks forming part of the structure.

Sea injection and overboard discharge valves and cocks.

Inspection of propellers, rudders and under water fittings.

Pressure vessel and associate mountings of an air pressure/salt water system having a working pressure of more than 275 kPa.

Four Yearly Surveys

Each screw and tube shaft.

Anchors and cables to range.

Chain locker internally.

Tanks forming part of the hull, other than oil tanks, internally.

Void spaces internally.

Compressed air pressure vessels having a working pressure of more than 275 kPa and associated mountings.

Pressure vessel and associated mountings of an air pressure/fresh water system having a working pressure of more than 275 kPa.

Cargo handling, Fishing and trawling gear.

Insulation test of all electrical installations above 32V A.C. or D.C.

Eight Yearly Surveys

Each rudder stock and rudder stock bearing

Steering gear.

Hull in way of removable ballast.

Selected sections of internal structure in way of refrigerated space.

Twelve Yearly Surveys

Fuel oil tanks internally

Corrosion and Deterioration

Deterioration of Timber

Fungal Attack

Breakdown of wood by fungi, commonly called rot or decay, can occur in timber whenever the moisture content rises above 20 to 25 percent. The fungi which cause decay spread by means of microscopic spores which are usually present in the air, so that any moist susceptible timber, even in almost completely sealed cavities, is subject to attack.

Warning signs of decay are:

Paint or varnish failure

A musty smell like mushrooms

Fruiting bodies, like toadstools, spongy growths, or soft incrustations of various colours

Mycelium, generally white threadlike growth, sometimes thick like cotton wool

Any softening, cracking or other physical breakdown of the wood

Marine Insect Attack

Timber may be attacked by any of the following, depending upon conditions:

Termites and White Ants

Subterranean types

Tree dwelling type

Dry wood type

All three of these varieties dislike the light and may be exterminated by the use of proprietary poisons.

Lyctus Borers

These only attack hardwoods which have sapwoods containing a high starch content. Fortunately 33% of Australian hardwoods are immune from attack. The attack becomes evident when an accumulation of fine flour dust appears on the surface of the timber. This borer may be exterminated by the use of proprietary poisons.

Marine Borers

The pill bug - a crustacean

The gribble - a crustacean

The shipworm or toredo - a mollusc

The crustacean borers cause the typical "hour glass" type of wastage seen in neglected piles of wharves, etc. If allowed to go unchecked they are responsible for considerable damage to the underwater section of wooden vessels. Sometimes they are referred to as "putty borers".

The toredo commences life as free swimming larva which attach to submerged timber and immediately begin to bore. In Australian waters they may reach a length of up to 1 metre. They use the attached wood as habitation, the worm feeding on minute marine life in the surrounding water. For the owners of wooden vessels these borers are a constant worry. Prevention of attack from both forms of marine borer is possible by deep and total impregnation of the timber with creosote or proprietary preservatives. An alternative by costly procedure is metal sheathing.

Corrosion of metal

Corrosion is the alteration and decomposition of metals or alloys by direct chemical attack or by persistent electrochemical reactions. Corrosion can be classified as:

Chemical corrosion. Electrochemical corrosion.

Chemical Corrosion

This is the attack of metals by solutions of acids or alkaline which will chemically combine with the metal to form entirely new products. The material can be considered as being dissolved in the solution. Such attack is usually caused by spillage of liquids such as battery acids, galley refuse, or in toilet areas.1.2.2 Electrochemical Corrosion

This is the most common type of corrosion. It is caused by very small electrical currents flowing between one metallic area to another. These electrical currents cause the material which is being corroded to change to a completely different substance; for example, steel changes to rust. Whether the corrosion takes place below the waterline, or above the waterline, the presence of both oxygen and an electrolyte (i.e. a conducting solution) play an important part. Saltwater is a liquid which encourages corrosion because it is an excellent conductor of electricity. Corrosion is indicated by the presence of rust or wastage of a metal.

The galvanic Scale of metals comparative reactivity.

ANODIC END

(GREATER TENDENCY TO CORRODE)

1 MAGNESIUM

2 ZINC

3 ALUMINUM ALLOYS

4 CADMIUM

5 MILD STEEL

6 CAST IRON

7 NICKEL CAST IRON

8 ALUMINIUM BRONZE

9 BRASSES

10 TIN

11 COPPER

12 LEAD-TIN SOLDERS

13 ALUMINIUM BRASS

14 MANGANESE BRONZE

15 SILICON BRONZE

16 TIN BRONZES (GUNMETAL)

17 STAINLESS STEEL 400 SERIES

18 NICKEL SILVER

19 NICKEL -CHROMIUM ALLOYS

20 LEAD

21 COPPER NICKEL

22 BRONZES

23 NICKEL -SILVER

24 COPPER -NICKEL ALLOYS

25 SILVER SOLDER

26 NICKEL

27 SILVER

28 STAINLESS STEELS 302, 304

29 MONEL

30 STAINLESS STEELS 316, 317

31 TITANIUM

32 GOLD

33 PLATINUM

34 GRAPHITE

CATHODIC END (noble)

Preservation of Structures

Preservation of Timber

The following precautions will keep the risk of fungal and insect attack to a minimum.

Ensure good ventilation throughout the boat, particularly when it is lying idle.

Make sure rainwater cannot get in.

Prevent condensation by ventilation. Where it is unavoidable eg. on insides of windows, use water-repellent preservative on woodwork.

Use a water soluble preservative in the bilge water. A cheap and effective one can be made by dissolving 0.65 Kg of borax and 0.45 Kg of boric acid in 4 litres of hot water. This mixture is non-corrosive and harmless to animals.

Inspect the vessel’s timbers for decay regularly, at least every 6 months. If decay is found act at once, a few weeks in summer is enough for major damage to be done.

Use a preservative from a variety of preservatives that have been developed for the successful treatment of timber for decay resistance.

Use a proprietary poison for extermination of marine insects.

Preservation of Metals

There are two ways of preventing corrosion.

1. By providing a piece of material which will corrode in preference to the vessel. Such a substance is usually found attached to the hull near the propeller or attached inside a tank, in the form of a sacrificial anode. When two metals in contact with each other result in one of the metals corroding, the metal which is preserved is called more "Noble" than the metal that corrodes.

In such cases aluminium will corrode in preference to steel; steel will corrode in preference to brass; brass will corrode in preference to stainless steel. Different metals should not be used in close contact unless there is good insulation between them; for example, it is bad practice to connect a steel valve to an aluminium hull, without insulation. The aluminium may corrode around the steel.

Lead, in contact with aluminium will cause rapid wasting of the aluminium. For this reason, lead based paints must never be used on aluminium hulls. Lead incidentally, is more noble than steel, but the problem is not nearly as noticeable.

2. By coating the surface with a substance such as paint. Paint sticks closely to any surface to which it is applied and prevents corrosion. In order to ensure that the bond between the paint and the surface is good the surface must be properly prepared.

In particular -

Any cracked or flaking paint should be removed.

The surface should be clean, dry and free from salt, oil, grease etc.

Any corrosion should be removed.

Any internal repairs to the surface should be completed.

It is beyond the scope of this learner’s guide to describe every type of paint there is, but some of the common types of paints are as follows:

Anti-corrosive Paints - used on metal surfaces to prevent corrosion from occurring.

Heat Resistant Paints - either sprayed aluminium or aluminium/graphite pigments.

Fire Retardant Paints - the action of these paints is that as they burn, gasses are given off which blanket the flame and slow or stop the combustion reaction.

Anti-fouling Paints - used on the hull to prevent the growth of marine organisms.

Barrier Paints - in the case of painting an underwater section with a new coat of anti-fouling, unless the old system is completely removed, it is essential that a coat of barrier paint is used between the old and the new coats of anti-fouling.

This is because the solvent in the new paint will react with the old and some of the poison will leach down through the old paint thereby reducing the amount available to come out of the new coat to seaward.

Likewise when using a ‘high performance’ 2 part paint over the top of a coat of conventional paint, the coats must be separated by a coat of barrier paint. The chemical reaction occurring in the HP paint will damage the underlying conventional paint.

Non Skid Paints - used on decks and steps to prevent slippage. Generally around door entrances, windlass area, boarding areas and on steel step ladders.

Paints can be applied by brush, roller or spray gun. In all cases you should refer to the manufacturer’s instructions on the recommended procedure, materials and safety precautions. This information is usually available from the paint container itself.

Glues and Sealants

Glues

There are six main glue types commonly used in boats:

Animal Glues & Resins:

Non waterproof and unsuitable for exterior use.

PVA (Polyvinyl Acetate):

Non waterproof and unsuitable for exterior use.

Rubber:

Contact adhesives that may be natural or synthetic. They are applied to both surfaces and allowed to partially dry before bonding together.

Melamine-Urea:

Cascamite (Casco urea formaldehyde) is a powder that is mixed with water with only a few hours shelf life. It is water resistant but brittle with poor filling qualities..

Aerolite is a two part catalyst and resin powder with water mix. The powder & water mix has a shelf life of a few days.The clear catalyst is applied to one surface and creamy resin applied to the other, allowing the coating of all surfaces prior to the event of bonding. Useful in tricky clamping up operations such as laminating multiple timbers or stitch and glue construction where time is a consideration.

Epoxies:

Two part with a hardener and a resin and a shelf life of an hour or two, epoxy resin glues are now universally used in marine timber construction. They are waterproof, very strong but do not penetrate the end grain of timber. The West System successfully uses additives and extenders to modify the qualities of epoxy resins for composite construction.

Resorcinols:

Aerodux or Cascophen are superior two parts with good spreading qualities. They are fully waterproof and UV resistant with a few days shelf life after mixing. They are not gap filling.

Rubber=1 Melamine Urea=2 Epoxy Resins=3 Resorcinols=4

| APPLICATIONS FOR TYPES OF GLUES |

||||||

| Metal |

Fabric |

Rubber |

Wood |

Paper |

Ceramic |

|

| Metal |

2 3 |

1 |

1 2 3 |

1 3 |

1 |

2 3 |

| Fabric |

1 |

1 |

1 |

1 |

1 |

1 |

| Rubber |

1 2 3 |

1 |

1 2 3 |

1 2 |

1 |

1 |

| Wood |

1 3 |

1 |

1 2 |

2 3 4 |

1 |

1 3 |

| Paper |

1 |

1 |

1 |

1 |

1 |

1 2 3 |

| Ceramic |

2 3 |

1 |

1 2 |

1 2 |

1 |

2 |

| Thermoplastic |

1 2 3 |

1 |

1 |

1 |

1 |

1 |

Modern bedding sealants are increasingly being used as adhesives with success.

Sealants

Sealants are used to form tough but flexible gaskets between fittings for insulation, waterproofing and increasingly as a bedding adhesive.

Traditional sealants:

Shellac:

Shellac, a natural resin, is nowadays more commonly associated with French polish for furniture finishing. It is dissolved in methylated spirit and was used as a bedding material under decking as it does not dissolved in water or by the action of the oils in wood.

Tar:

Stockholm tar with its distinctive smell is still used to waterproof natural fibre ropes, yarn and canvas.

Pitch:

A solid form of tar at normal temperatures, it is melted and laid into the gaps between deck planking to seal them. Geofferies Marine Glue

Putty:

A linseed oil and chalk mixture that was fortified with powdered white lead (lead oxide) but is now commonly mixed with the less toxic red metal primer paint, and used to seal the plank seams in timber carvel construction.

Mastic:

Very slow drying natural or mineral oil pastes that provides a sticky waterproof seal that is flexible. As mastics age they dry, shrink and crack away from the surfaces. They are most successfully used as gaskets rather than surface fillets or beadings.

Modern sealants:

Polyurethane:

Form a permanent bond and should not be used for fittings that require to be moved. Not suitable for ABS type plastics. Some are not suitable for overpainting. Liquid nails, Construction adhesive

Polysulphide:

Single and two part varieties provide a rubber like flexible sealant. They can be premoulded to form gaskets and components can be disassembled with varying degrees of ease. They must be applied to dry surfaces. Oily timber will require sealing with a primer. Most can be sanded and overpainted. Sikaflex.

Silicone:

Bond well to all surfaces to form a highly elastic seal. Most can be disassembled with ease and are not paintable. They are readily available and you will get a quality of Sealant that matches the price you are willing to pay for.

Exellent=1 Very good=2 Good=3 Not Recommended=4

Sealant/Bedding table |

|||

Material |

Polysulphide |

Polyurethane |

Silicone |

ABS to GRP |

4 |

4 |

3 |

ABS to Wood |

4 |

4 |

3 |

Deck/hull joints |

1 |

1 |

2 |

Deck seams |

1 |

4 |

4 |

Electrical insulation |

2 |

1 |

1 |

GRP to GRP |

2 |

1 |

2 |

GRP to glass |

2 |

1 |

2 |

Glass to metal |

2 |

1 |

2 |

| Glass to vinyl |

4 |

4 |

3 |

Glass to wood |

1 |

2 |

3 |

| Metal to wood |

1 |

2 |

3 |

| GRP to metal |

1 |

1 |

2 |

Plank seams underwater |

1 |

4 |

4 |

| GRP to plastic |

4 |

4 |

2 |

| Plastic to wood |

4 |

4 |

3 |

| GRP to wood |

1 |

1 |

2 |

Working with Confined spaces

General duties of employers and employees

Duties of employers

Under all NOHSC standards and codes, employers have a duty to:

- implement a systematic process of hazard identification, risk assessment, risk control and review in the workplace;

- make sure employees receive appropriate training, instruction and supervision, including induction and ongoing training;

- obtain and provide appropriate information;

- consult with employees likely to be exposed to risks, and with their health and safety representatives;

- keep appropriate records.

Additional or more specific requirements apply in some areas.

hazardous substances;

- HIV/AIDS and hepatitis B;

- major hazard facilities;

- plant;

- working in confined spaces.

Duties of employees

Under all NOHSC standards and codes, employees have a duty to:

- comply, as far as they can, with all activities carried out in accordance with the standard

- report to their employer anything that might affect the employer’s compliance with the standard.

What is a Confined Space?

Confined spaces are fully or partially enclosed areas which aren’t designed to be normal places of work, and where entry and exit are restricted. They include things like storage tanks, silos, pits or degreasers, pipes, shafts or ducts, or confined space onboard ships.

Working inside spaces like this (including putting one’s head or upper body inside them) can be dangerous for various reasons. Fatalities or severe injuries can occur because:

- there’s not enough oxygen, or too much oxygen (leaking from an oxygen supply, for example);

- the atmosphere or surfaces inside are contaminated,

- steam, water, or other gases or liquids may enter the space in an uncontrolled way;

- there is a risk of suffocation (eg by grain, sand, flour), electrocution, explosion or fire.

Confined spaces can increase the risk of injury from other hazards too—such as equipment operating in the space, noise (tasks such as hammering may become louder), radiation, or temperature (conditions may be too hot or too cold as a result of the work process or the weather conditions, bad ventilation or inappropriate clothing).The constraints of the space can also make manual handling injuries and falls more likely.

Standards and codes of practice

Joint

National Standard for Safe Working in a Confined Space

Australian Standard AS2865-1995 (produced jointly by Standards Australia and

the NOHSC):

A set of requirements for employers (and designers) about:

- how to eliminate or minimise the need to enter confined spaces; and

- how to protect the health and safety of anyone who needs to enter a confined space.

Special duties

In addition to the duties outlined previously, employers must also:

- ensure that any modifications to a confined space do not make entry and exit more difficult;

- ensure that no one enters a confined space without an entry permit;

- ensure that appropriate rescue and first aid procedures are planned, established and rehearsed.

- keep the following records:

- entry permits (for one month);

- risk assessment reports (for five years);

- training (for the term of the employee’s employment).

The national standard also sets out various duties which apply to people who design, manufacture or supply confined spaces.

Identifying hazards and assessing risks

Getting Started

Start by listing the confined spaces in your workplace, noting any work associated with them (regular maintenance, for example) and whether it is necessary to enter the space to perform the work.

You’re looking for:

- hazards associated with entering the confined space itself, as well as

- hazards associated with what is actually to be done inside the space.

Use checklists, perhaps based on those in the accompanying show.

Controlling risks

1. Options which eliminate the hazard

The best option is eliminate the need to enter the confined space at all—use tanks designed to be self-cleaning, for example, or equipped with observation windows.

2. Options which minimise the risk

Substitution: If it’s absolutely necessary to work in a confined space, substitutions can be made to ensure the work itself is as safe as possible—using a non-flammable solvent instead of a flammable one, for example, or a brush instead of aerosol application.

Isolation: The space should be isolated from all potentially hazardous services to prevent accidental activation of things like machinery, accidental energisation, or accidental introduction of contaminants or other unwanted materials through piping, vents, drains etc.

Engineering controls may include mechanisms for lockouts, for cleaning contaminants from the confined space, for monitoring conditions inside the space, or for ensuring the atmosphere (including oxygen level, pressure and temperature) is safe (and remains safe all the time anyone is inside the space).

Try to get the design right in the first place: If the space can’t be designed to eliminate the need for entry, the design of the space should minimise the risk to anyone entering or working inside it (including providing safe means of exit and entry).

3. Backup controls

Safe work practice should be designed to ensure that, wherever a risk to health and safety has been identified:

- no-one enters a confined space without an entry permit, and without at least one person standing by outside;

- suitable signs are erected outside while people are inside;

- the confined space is only returned to service after making sure (and acknowledging in writing) that the work is finished and no one remains inside,

- suitable procedures are in place for rescue, first aid and fire suppression.

Personal protective equipment such as respiratory equipment, safety harnesses and protective clothing, may be used when risks cannot be sufficiently controlled using other means, or as a temporary measure until other controls can be implemented.

Risk factors within confined spaces

Risk factors are things which could affect the risk of harm from working in confined spaces

- Nature of the confined space

Risk increases with:

- unsound or insecure structures

- low visibility or lack of illumination

- size and shape which restricts movement

- difficult or obstructed entry/exit points

- presence of moving equipment which may crush, or trap a person

- potential for uncontrolled introduction of steam, water, or other gas or liquid.

State of the atmosphere inside the space

Risk increases with:

- presence of inert gases which dilute air

- presence of contaminants (gases, vapours, fumes, particulates)

- presence of explosive or volatile substances

- lack of ventilation

- higher or lower than normal temperature and/or atmospheric pressure

- Substances currently or last contained

Risk increases with:

- substances (either organic or inorganic) which have been slowly oxidising (using available oxygen)

- substances which absorb oxygen (grains, chemicals, soils)

- substances which leave contaminants on surfaces (solids, liquids, sludges)

- presence of solid materials (eg grains, sand, flour, fertiliser) which can cause suffocation

- Work in adjacent areas

- Risk may increase with hot work or use of moving equipment such as forklifts in adjacent areas

The requirements of the work to be done

Risk increases with:

- the need for physical activity, which increases the body’s use of oxygen and raises body temperatures

- the use of equipment which could leak excess oxygen into the atmosphere

- the use of equipment which could make entry/exit difficult

- the use of processes which release contaminants (eg painting with toxic or flammable substances, welding or brazing with metals producing toxic fumes)

- the use of processes involving combustion(which use up oxygen)

- the need for hot work

- the use of equipment which produces radiation (eg lasers, welders, radiation gauges)

- processes producing noise which may be amplified by the confined space

Number of people inside the space

- Risk increases the more people there are inside (although two may be safer than one in some circumstances??)

The length of time spent inside the space

- Risk increases the longer or more often work is required inside a confined space.

Number of people outside the space

- There should be enough people outside to maintain essential equipment, monitor progress and carry out rescue procedures

Fitness, skills and experience of employees

- Risk increases for inexperienced or untrained employees.

- Use and effectiveness of control measures

Training tips

Training programs about working in confined spaces should cover:

- hazards associated with such working conditions;

- risk assessment procedures and control measures;

- emergency procedures;

- selection, use, fitting and maintenance of safety equipment.

Training should be provided for people working in or on confined spaces, as well as people who:

- are on standby during confined space work

- issue entry permits;

- design and lay out the workplace;

- manage or supervise people working in or near confined spaces,

- maintain equipment used for confined space work;

- buy, distribute, fit or maintain personal protective equipment

- are involved in rescue and first aid procedures.

Advice and training materials can be obtained from State and Territory governments, and employer and employee groups.

Marine Pollution

The enormous growth in the maritime transport of oil and the size of tankers, the increasing amount of chemicals being carried by sea and a growing concern for the world’s environment as a whole made many feel that the 1954 OILPOL Convention was no longer adequate, despite the various amendments which had been adopted. In 1969 the IMO Assembly (again prompted partly by the TORREY CANYON incident two years previously) decided to arrange an international conference to consider a completely new convention. The Conference duly met in London in 1973.

The Convention which resulted - the International Convention for the Prevention of Pollution from Ships (MARPOL) - is the most ambitious international treaty covering maritime pollution ever adopted. It deals not only with oil but with all forms of marine pollution from ships except the disposal of land-generated waste into the sea by dumping (which was covered by another Convention adopted the previous year).

As a result, we have two major Acts of Parliament in this country regarding pollution from ships:

1 The Protection of the Sea (Prevention of Pollution from Ships) Act 1983.

2 The Environmental Protection (Sea Dumping) Act 1981.

In New South Wales and other States, there is a parallel legislation (e.g., NSW Marine Act 1987).

Under

the International Convention for the Prevention of Pollution from Ships 1973/78

(known as MARPOL), all of the above applies. In

The MARPOL Convention includes 6 technical Annexes. Annexes I and II, dealing with oil and bulk noxious liquid substances respectively, are mandatory, in the sense that ratification of the Convention is impossible without ratification of these Annexes. Annexes III, IV, V and VI, dealing respectively with harmful substances in packaged forms, sewage, garbage and air pollution are optional. The Convention also has two Protocols, dealing respectively with reports of incidents involving harmful substances and arbitration.

Entry into force is as follows:

MARPOL

73/78 2 October 1983 (international) 14 January 1988 (

Annex

I 2

October 1983 (international) 14 January 1988 (

Annex

II 6

April 1987 (international) 14 January 1988 (

Annex

III 1

July 1992 (international) 10 January 1995 (

Annex

IV 27

September 2003 (international) expected 2004 (

Annex

V 31

December 1988 (international) 14 November 1990 (

Annex VI Not yet in force (expected 2004)

The Annexes can be summarised as follows:

Annex I Oil - oil mixtures, distillates, gasoline, jet fuels, etc.

Annex II Noxious liquid substances - mainly chemicals including acids, alcohols, castor oil, hydrogen peroxide, pentane, etc. Also citric juice, glycerine, milk, molasses, wine, etc.

Annex III Harmful substances in packaged form - includes freight containers, portable tanks, road and rail tank wagons, etc.

Annex IV Sewage - wastes from toilets, drainage from medical premises, drainage from spaces containing live animals, etc.

Annex V Garbage - plastic bags, synthetic ropes, food wastes, paper products,

glass, metal, crockery, packaging material, synthetic fishing nets, etc.

Annex VI Air Pollution

Annex I - Oil

Except where otherwise stated, these regulations apply to all tankers of 50 gross tons (about 30 metres in length) and above and other ships of 400 gross tons (about 40 metres) and above.

A complete ban on operational discharges of oil from ships except under the following conditions:

For all ships,

1 The rate at which oil may be discharged must not exceed 60 litres per mile travelled by the ship;

2 The oil content of any bilge water discharged must be below 100 parts per million;

3 Ship must be more than 12 miles from nearest land; and

4 Ship must have in operation an approved oil discharge monitoring and control system, oily water separating equipment or oil filtering equipment.

Parties to the Convention are obliged to provide adequate facilities for the reception of residues and oily mixtures at oil loading terminals, repair ports, etc.

Oil tankers must have the equipment necessary to operate the “load on top system” or to retain oily residues on board until they can be discharged into shore reception facilities. This equipment includes slop tanks, oily-water separating equipment or filtering systems, oil content meters, oil discharge monitoring and control systems, sludge tanks and suitable pumping and piping arrangements.

All ships of 400 gross tonnage and above - including non-tankers - must be equipped with oily-water separating equipment or a filtering system for the discharge of machinery space bilges.

Every oil tanker of 150 tons gross tonnage and above, and every other ship of 400 tons gross tonnage and above will be subject to the survey specified below:

(a) an initial survey before the ship is put in service, or before the Certificate is issued for the first time, to ensure that the structure, equipment, systems, fittings, arrangements, and material fully comply with the requirements of the Annex;

(b) a period survey at intervals of five years before the re-issue of the Certificate, for the same reasons stated in (a);

(c) one intermediate survey held not before six months prior to, nor later than six months after the halfway date of the Certificate’s period of validity, to ensure that the equipment and associated pump and piping systems, including oil discharge monitoring and control systems, crude oil washing systems, oily water separating equipment and oil filtering systems, fully comply with the requirements of the Annex;

(d) an annual survey held within three months before or after the anniversary date of the Certificate; except when the annual survey coincides with the intermediate survey, then the annual survey will not be necessary.

For existing crude oil tankers a third alternative was permissible for a period of two to four years after entry into force of MARPOL 73/78. This was called dedicated ‘clean ballast tanks’ (CBT) and was a system whereby certain tanks were dedicated solely to the carriage of ballast water: This was cheaper than a full SBT system, since it utilised existing pumping and piping, but when the period of grace expired (2 October 1987), other systems had to be used.

National Plan To Combat Marine Pollution

This was set up after the grounding of the Oceanic Grandeur in Torres Strait in April 1970.

Stockpiles

of dispersant materials and equipment are set up at 9 ports around

Pollution Prevention From “Small” Vessels

• Observe anti-spill and fire precautions when re-fuelling.

• Don’t discharge oily bilges within 12 nautical miles from coast. Observe the above guidelines when discharging outside 12 miles. Oily bilges must be discharged into a mobile or a shore based pump-out facility. Observe the above “large vessel” guidelines when discharging at sea. Bilge water can easily be cleaned by installing an oil absorbent pad or a oily water separator near the bilge pump. Bilge sponges are available from most chandlers.

• Engine oil must only be discharged into an oil reception barge or a shore facility.

• If a vessel is not fitted with a separate oily waste tank, oily bilge water should be pumped into a container on deck for disposal when ashore.

• No discharge of any type is permitted in the specially protected area of the Great Barrier Reef. This means that vessels are prevented from discharging unprocessed garbage within 12 nautical miles of the outer edge of the reef - in some places this is as much as 162 nautical miles from the Queensland coast.

• You are required to report any polluting spill from your own vessel, and, requested to report sighting of any other.

In Case Of An Oil Spill

• Cease operation

• Ease pressure on overflowing tank.

• Sound emergency alarm

• Ban smoking anywhere on board

• Take all fire precautions

• Control spill

• Inform authorities

• Clean up on deck

Fuel Expansion In Hot Weather

Fuel

expands in volume about 0.5% per 1°C rise in temperature. Therefore, with

a 10° rise in air temperature - a common daily fluctuation in

Great Barrier Reef

Under MARPOL, no discharge of any type is permitted in the area of Great Barrier Reef. In some cases this can be as much as 150 nautical miles from the Queensland coast. Where discharges are prohibited within a certain distance from the land these distances are measured from the outer edge of the reef.

A POLPREP

(1) Each report shall contain in general:

(a) identity of the ship;

(b) the time and date of the occurrence of the incident;

(c) the geographic position of the ship when the incident occurred;

(d) the wind and sea conditions prevailing at the time of the incident; and

(e) relevant details respecting the condition of the ship.

(2) Each report shall contain, in particular:

(a) a clear indication or description of the harmful substances involved, including, if possible, the correct technical names of such substances (trade names should not be used in place of the correct technical names);

(b) a statement or estimate of the quantities; concentrations and likely conditions of harmful substances discharged or likely to be discharged into the sea; and

(c) where relevant, a description of the packaging and identifying marks; and

(d) if possible, the names of the consignor, consignee or manufacturer.

(3) Each report shall clearly indicate whether the harmful substance discharged, or likely to be discharged is oil, a noxious liquid substance, a noxious solid substance or a noxious gaseous substance and whether such substance was or is carried in bulk or contained in packaged form, freight containers, portable tanks, or road and rail tank wagons.

(4) Each report shall be supplemented as necessary by any other relevant information requested by a recipient of the report or which the person sending the report deems appropriate.

Spill Or Discharge By Ship

A1 Ship: name, size, type, call sign/ship station identity and flag

A2 Name, address and contact details of owner and agent of ship/place on land/purpose-built pipeline/apparatus

A3 Position of discharge and position of place on land/purpose-built pipeline/apparatus

B Date and time of event

Note: Express as Universal Co-ordinated Time

C Position: latitude and longitude, or

D Position: true bearing and distance

Note: Give C or D

E True course

F Speed in knots

L Route information: intended track

M Radio communications: means of communication

N Time of next report

Note: Express as Universal Co-ordinated Time

P1 Type of oil or the correct technical name of the noxious liquid substances on board

2 UN numbers

3 Pollution category (A, B, C or D) for each noxious liquid substance

4 Names of manufacturers of substances or consignee or consignor

5 Estimate of the quantity of each substance

Note: Include item P in the case of probable discharge