MARINE ENGINES & PROPULSION

Ranger Hope © 2015

View as a Pdf file

This text is provided for research

and study only on the understanding that users exercise due care and do not

neglect any precaution which may be required by the ordinary practice of seamen

or current licensing legislation with respect to its use. No copying is permitted and no liability is

accepted resulting from use.

Chapter 1: Principles of internal combustion engines

1.4 Timing-

valves and injection

1.5 Air supply

- turbo charging, after coolers

1.6 Engine

protection – devices

Chapter 2: Fuel storage and handling

2.1 Fuel storage

and survey compliance

Chapter 3: Fuel supply, injection and

control

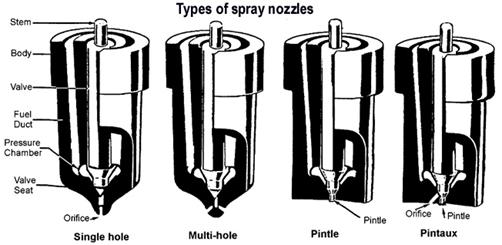

3.3 Fuel injectors, combustion chamber

3.4 Diesel fuel

injection pumps

Chapter 4: Lubrication systems

4.1 Lubrication purpose and components

4.3 Contamination, analysis and servicing

5.3 Faults, maintenance and servicing

Chapter 6: Gearing and tailshafts

6.1 Gears and

clutch mechanisms

6.2 Reverse and

reduction gear boxes

6.3 The shaft

driven transmission system

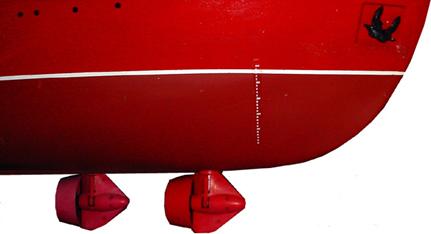

Chapter 7: Propellers and

propulsion systems

7.2 Methods of

propulsion reversal

7.3 Other

propulsion systems -

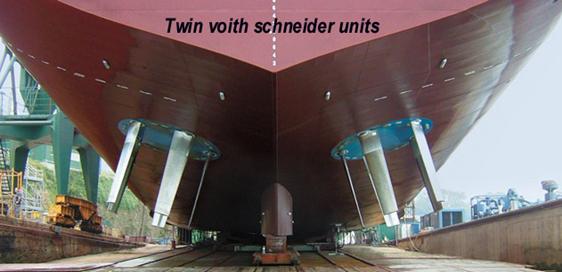

Azimuth thrusters, Voith Schneider, Jets.

Chapter 8: Operating

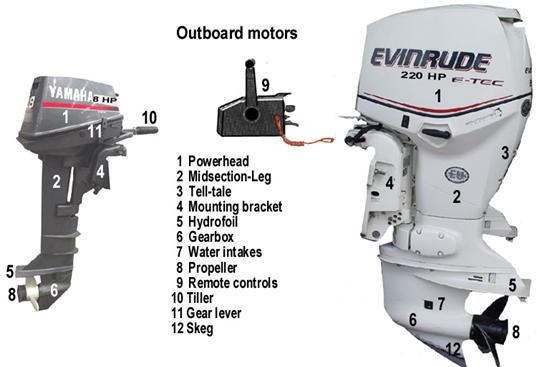

an outboard motor

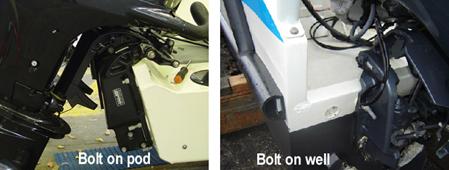

8.1 Outboard systems and performance

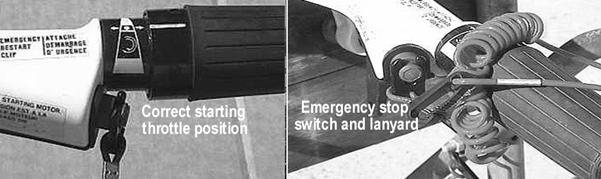

8.3 Engine protection and devices

8.4 Start up,

operation and shut down

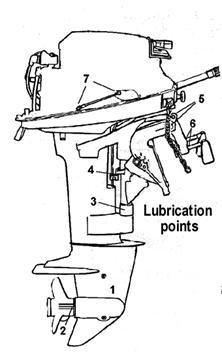

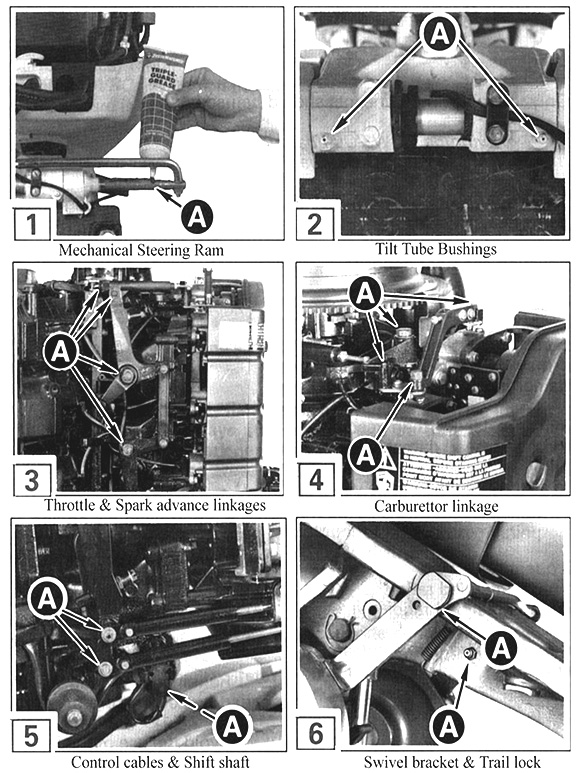

8.5 Preventative maintenance schedule

Chapter 9: Operating an inboard

diesel engine

9.2 Engine protection and devices

9.3 Start up,

operation and shut down

9.5 Safety

aspects when working on engines

9.6 Preventative maintenance schedule

10.4 Loss of

lubricating oil pressure

10.6 Excessive vibration, fluctuation of engine

revolutions

Introduction

This book describes the main engines, auxiliary motors and propulsion systems found on small commercial vessels of less than 80 metres (less than 500 tons).

Marine engines are described by their crankshafts’ revolutions per minute (rpm) – typically as low speed engines (less than 400 rpm), medium speed engines (400 -1000 rpm) or high speed engines (over 1000 rpm).

As this small commercial fleet is principally fitted with high speed diesel inboard engines, or in the smaller craft increasingly with high speed petrol outboard engines, these are described most fully.

Definitions

The following technical terms are used in this text.

Bottom dead centre – the position where the piston has reached its furthest distance from the cylinder head, and will subsequently reverse its direction of stroke (bdc).

Calorific value - fuel contains heat energy which is released in the combustion process called the fuel’s calorific value, measured in joules per kilogram of fuel.

Cam lift - the distance that the peak of the cam’s lobe extends from the round which is the same as the valve opening plus the tappet clearance (valve lash).

The cam lift profile causes the valve to open rapidly then stay open momentarily before rapidly re-closing. Dwell is the angle of the cam over which the valve remains temporarily in the fully open position.

Compression ratio - is the comparison the volume of the cylinder as the piston sweeps from BDC position up to TDC position, sometimes called the ratio of the unswept volume to the swept volume of the cylinder. A compression ratio of 12:1 would mean that the air (in diesel engines) or air/fuel (in petrol engines) has been compressed to one-twelfth its original volume. Diesel engines need a high compression ratio heat the compressed air sufficiently to ignite the fuel.

Compression ratio =

maximum cylinder volume ÷ minimum

cylinder volume

Flash point - in order to catch on fire, a material must be heated

sufficiently to cause it to partially vaporize. The lowest temperature at which the vapour

arising from the fuel gives off a flammable mixture that will ignite when flame

is momentarily applied under defined test conditions is called its flash

point. Technically petrol and diesel are cocktails of hydrocarbons of

different flash points. Commonly from - 40°C to 0°C for petrol and 60°C for

diesel is regarded as the temperature that they will burn. (Diesel’s lower

volatility means it is safer to use than petrol). If a fire is cooled below its

flash point then the flame will not be sustained.

Force - an influence which tends to change the motion or direction of a body (such as pushing or pulling) measured in newtons (N). A force can either:

Start moving a body from rest or bring a moving body to rest.

Increase or decrease the speed of a body.

Change the direction of motion of a moving body.

Heat transfer - Heat moves (transfers) in

three ways:

Convection Heat moving within a liquid or

gas.

Conduction Heat moving through a solid.

Radiation Heat energy traveling out as

heat rays (direct heat).

The hottest air or water experiencing convection move

upwards, the coolest downwards, thus forming a gyre rotation in a sealed

system. Conducted

heat is movement away from its origin along metal components. Radiated heat (from

exhaust manifolds) may char or set it alight material that is close, consequently

removing surrounding flammable materials (boundary clearance) is essential to

limit spread of fire.

Power - is the amount of work or energy expended in a given time or the capacity to do work measured as Watts (W). A watt is work at the rate of one joule per second.

Power = Force x

Distance = newton/metres per second or joules per second.

Time in seconds

Force is in newtons (N), distance in metres (m) and time in seconds (s). Therefore the formula first answer is in units of Nm/s or j/s. However as1 Nm = 1 joule and 1 joule per second = 1 watt so the final answer converts to watts. Engine power is measured in kilowatts (kW) -1000 W = 1 kW.

Scavenging - describes the elimination of the burned exhaust gases from a cylinder, pushed out by the incoming stream of air induction. Valve overlap assists in the process.

Thermal efficiency - is a comparison of the work done at the flywheel to the amount of energy contained in the fuel, and is expressed as a percentage.

Top dead centre - the position when the piston has reached its least distance from the cylinder head, and will subsequently reverse its direction of stroke (tdc).

Torque - describes a force tending to cause a rotational movement about a point, also called a turning or twisting effort. Torque is the force exerted, but not moved, over a distance measured in newton/metres (Nm). For instance, the force the connecting rod exerts on the crankshaft.

Torque = Force x

Distance in newton/metres (Nm).

Turbulence - a rapidly swirling motion of the air as it enters the combustion chamber. In most engines it is deliberately induced as the violent movement helps ensure even mixing of the fuel and air. It enhances flame propagation speeding up the combustion process once the fuel has ignited.

Work - the amount of energy used to

overcome resistance in moving an applied force through a distance as Work = Force x Distance in joules

It could be described in newton/metres (Nm) as force is measured in newtons (N) and the distance is measured in metres (m).To prevent confusion between work and torque, the unit given to the formula for work is the joule (j), by conversion as:

One newton/metre =

one joule.

Volumetric efficiency - is the ratio between the swept volume of a cylinder (between tdc & bdc) and the actual volume of air drawn in during the induction stroke. The efficiency varies depending on the design, operating conditions and engine speed. A turbo charged engine will have a higher volumetric efficiency (in excess of 100%) than that of a normally aspirated engine.

Valve overlap - is the period which both the inlet valve and exhaust valve are open simultaneously. For instance, if the inlet and exhaust valve are both open at 10° before TDC to 3°after TDC the valve overlap is over a 13° angle.

The purpose of valve overlap is to ensure that are exhaust gases are discharged from the cylinder and the cylinder receives a fresh charge of air to make it more efficient when combustion next takes place. It also has a cooling effect.

Valve rotators - rotate a valve each time it opens to ensure even wear and prevent exhaust valves from localised burn out.

Chapter 1: Principles of

internal combustion engines

1.1 Operating principles

Combustion is the process in which fuel heated beyond its flash point ignites and gives off energy and the waste products as exhaust gasses (carbon dioxide, carbon monoxide and water). The three elements necessary for combustion (or fire) are:

Oxygen + Heat + Fuel =

Explosion or Fire

Internal combustion engines suck in air to access the oxygen and use hydrocarbon fuels including petrol, diesel and liquid propane gas.

The

internal combustion process

Internal combustion engines use successive explosions of atomised air and fuel mix to force a piston down a gas tight internal cylinder. The piston is connected through a big end bearing to a cranked shaft that is weighted by a flywheel to assist its rotary momentum. Thus with three primary moving parts (piston, connecting rod and crankshaft) the piston’s reciprocating motion drives the crankshaft’s rotary motion.

A sturdy metal casting of an engine block holds the internal parts and the many ancillary components required for smooth and continuous operation. These include:

A lubrication sump (oil reserve); a cylinder head with gas outlets and inlets; and in the drawing shown below, an over head camshaft driven timing gear within a rocker box. For it to work timing is everything. The fuel (diesel, petrol or gas) and air (oxygen) charge must be inserted, the exhaust removed and a compression seal reinstated at the precise instant for the explosive ignition. The heat and noise from multiple explosions as well as wear on metal surfaces must be minimised.

To ensure a gas tight compression seal, the cylinder liners in the engine block are bored to very tight tolerances and the barrel of the piston is grooved to accept close fitting sprung metal rings - that makes for a tight sliding fit against the cylinder walls.

In order to insert the fuel/air mix and exhaust the products of the combustion, sealable inlet and outlet passageways must be provided. Typically these passageways take the form of either ports (holes in the cylinder wall that are covered and uncovered by the passing of the piston) or by valves (steel stoppers that plug and unplug holes in the cylinder head at the correct timing intervals).

Basic features

The simplest engines often use ports and more the complex use valves, though hybrids like that shown below use both. The piston is connected to the big end bearing of the crankshaft by means of a connecting rod. The piston is forced down the cylinder by the expansion of combustion gases to turn the crankshaft. With the piston as low as it will go in the cylinder, it is said to be at bottom dead centre (bdc). The momentum of the flywheel weighted crankshaft rotating on its main bearings forces the piston back to the top of the cylinder, ready for the next explosion. When it is as high as it will go in the cylinder, it is at top dead centre (tdc).

The distance the piston moves from tdc to bdc is called the stroke of the engine.

The turning crankshaft drives the camshaft by means of timing gears (or by sprockets and a chain). In the drawing shown above, the side camshaft is driven by crankshaft gears. Oval cams on the camshaft open the inlet and exhaust valves at the correct time by means of push-rods actuating rockers. An inlet port (or alternately a valve) allows air or fuel/air mixture to be drawn into a cylinder ready for combustion, while an exhaust valve lets exhaust gas out of a cylinder.

The arrangement of ports or camshafts and valves differs depending on engine design. The drawing above shows a two stroke engine with its piston nearing tdc, its exhaust valve closed and inlet port covered, so compressing the fuel/air charge immediately prior to ignition. At the end of the power stroke the cam will open the exhaust valve to flush the cylinder ready for re-charge and re-ignition.

The work cycle

A sequence of four operations called the work cycle must occur for engines to work:

Induction – a charge of air (diesels) or air/fuel mix (petrol) is directed into the cylinder to provide the oxygen required for combustion.

Compression - the charge is compressed to optimise the result of combustion.

Power - the air/fuel mix (petrol) is ignited by a spark, or with diesels the fuel is injected to ignite in the superheated compressed air. The expansion of the gasses from this explosive ignition exerts a force upon the piston that turns the crankshaft.

Exhaust- The products of this explosion (the exhaust gasses) is ejected so the cycle can be repeated.

The work cycle of

induction (suck), compression (squeeze), power (bang) and exhaust (push) are

achieved by differing configurations or types of engines including four stroke or two stroke engines. The term stroke means the directional travel of

the piston along the cylinder from tdc - bdc or from bdc - tdc.

The four-stroke engine

takes two complete revolutions of the

crankshaft to complete the work cycle. The two-stroke does it in one complete revolution of the

crankshaft. This means that a two-stroke engine has twice as many power operations

as a four-stroke engine at the same speed, so it may produce more power and

acceleration but at the expense of fuel efficiency and reliability.

Petrol or diesel

Due to availability and convenience of handling, petrol (or

gasoline) and diesel (or distillate) are the most common small

vessel marine propulsion fuels. Larger vessels often use a cheaper and less

refined tarry fuel oil requiring heat to liquefy sufficiently for the

combustion process. Petrol and diesel are cocktails of hydrocarbons wth differing flash points, commonly from - 40°C to 0°C for

petrol and 60°C for diesel, this being the temperature that they will vapourize to ignite. Diesel’s higher flash point makes

it safer than petrol as any escaping fuel vapours can

pool in a boat’s bilges with consequent risk of explosion.

The diesel engine uses the piston’s sweep of the cylinder from bdc position up to tdc position to compress the inducted air, raising its pressure and consequent heat to such an extent (1000ºC) that when fuel is injected it immediately ignites. Diesel engines need a high compression ratio compressed the air sufficient to reach the temperature for ignition. A 16:1 to 20:1 compression ratio, common to small high speed diesel engines means that the air has been compressed to one-sixteenth or one twentieth of its original volume. The wall of the cylinder needs to be heavy gauge to contain the pressure.

Considerable power is needed to overcome that amount of compression to get a diesel engine started. Larger diesel engines have decompression levers that open the cylinder to the atmosphere so relieving the force needed for the starter mechanism to get the engine turning over. When the flywheel is spinning rapidly they are closed for the first compression and power operation to start.

The petrol engine, using the more flammable fuel, can ignite the fuel/air mix by an electrically generated ignition source at its spark plug, more fully described in Chapters 1.4 and 8.2. A compression ratio of 10:1, common to small high speed petrol engines means that the air has been compressed to one-tenth of its original volume, requiring less energy to turn over in starting than the diesel.

While advances in design are ever improving, the advantages and disadvantages of the typically ponderous but reliable diesel against the responsive but explosive petrol

is demonstrated in the proliferation of diesel engines for inboard installation (required for commercial vessels) and petrol engines for outboards. In short, the strengths and weaknesses of petrol versus diesel engines can be summarised as:

Petrol driven engines use fuel with high fire risk, require electrical sparking that is not ideal in a damp environment but can be low weight for power capacity with high acceleration performance.

Diesel driven engines operate using a fuel with lower fire risk, do not rely on electrical connections but can be heavy for power capacity with slow naturally aspired acceleration balanced by reliability and longevity. Though of a heavier build than petrol engines, in order to sustain the forces resulting from higher compression, they are known for producing working power (grunt) at lower speeds.

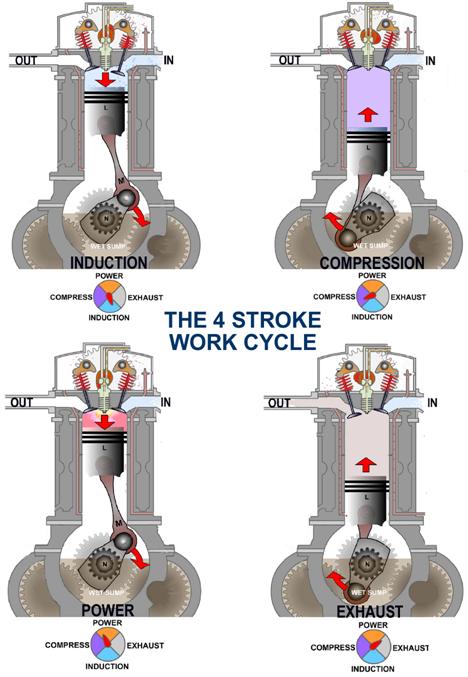

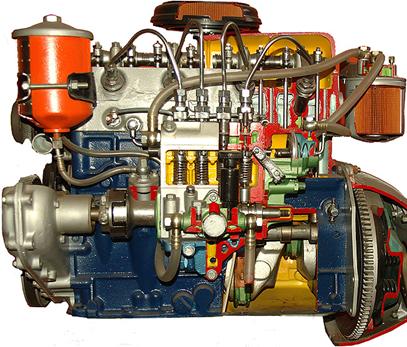

1.2 The four stroke engine

Four stroke engines can be diesel or petrol. The four strokes of a wet sump diesel engine are shown below with exhaust outlet marked (out), air inlet (in), piston (L), con rod (M) and crankshaft (N). This crankshaft revolves in a clockwise fashion.

Induction stroke-1

As the piston

nears tdc the inlet valve is opened by the camshaft’s

cam driven by the rotating crankshaft. As the crankshaft rotates further it

drags the piston down the cylinder sucking fresh air into the cylinder through

the inlet port and its inlet valve.

As the piston nears

bdc the inlet valve is closed, trapping the charge of

fresh air.

Compression-stroke 2

At near bdc both valves shut. As the crankshaft rotates it pushes the piston up the cylinder and so squeezes the trapped air (to about 5% of its normal volume). The compression of the air heats it up to about 500°C sufficient to ignite any diesel fuel.

Power stroke-3

Just before tdc the camshaft driven injector pump sprays a measure of fuel into the cylinder at high pressure through an injector. The atomised fuel sprayed mixes with the hot compressed air and explodes. As the piston passes tdc, the burning gas expands, driving the piston toward bdc, rotating the crankshaft and its attached weighted flywheel. The momentum energy of the heavy rotating flywheel keeps the engine rotating smoothly until the next power stroke.

Exhaust Stroke-4

Just before the piston reaches bdc, the exhaust valve opens and the pressure of the burnt gases is released into the exhaust outlet. As the piston passes bdc and rises up the cylinder it pushes the remaining burnt gases out of the cylinder through the exhaust valve. As the piston reaches tdc, the exhaust valve closes, and the engine is ready to repeat the work cycle.

The four stroke engine takes two complete revolutions of the crankshaft to complete the four strokes of this work cycle. A high speed engine’s crankshaft turns at more than 1200 revolutions per minute (rpm), or 20 revolutions per second, or 10 work cycles (40 strokes). Accurate valve timing is critical to efficient functioning. Typically wet sump type lubrication is used in four stroke diesel engines.

Four stroke cycle petrol engines

are similar in operation to four-stroke diesel

engines. Differences include that the fuel is pre-mixed with air in a carburettor. A fuel/air mixture rather

than pure air is drawn into the cylinder during induction though some petrol

engines use an injection system. In the power stroke, the petrol/air mix is ignited

by means of an electrical ignition system and spark plug, rather than the heat

of compression. The timing of the spark ignition for four-stroke petrol engines

is normally synchronised by the camshaft.

1.3 Two stroke engine

Simple valveless petrol two stroke engines

The work cycle of the simplest petrol engine pump or generator is shown below with exhaust outlet port marked (out), air/fuel inlet port (in), con rod (M), crankshaft (N), carburettor (K) and spark plug (B). This crankshaft revolves in a clockwise fashion. Two stroke engines take one crankshaft revolution to complete the four work cycle operations. The simplest two strokes achieve this by using ports in the cylinder wall that are sealed or exposed during the piston’s sweep along the cylinder. Typically a proportion of oil (ratio 16 to 30:1) is added to the fuel to lubricate moving parts, this system being described as dry sump lubrication.

Power and exhaust operations-stroke 1

Just before tdc the piston is positioned above both inlet and outlet ports so sealing the cylinder with its pressurised charge of fuel/air mix. The crankshaft synchronises the timing that releases a high voltage impulse to the spark plug to explode the fuel/air mix. As the piston passes tdc, the burning gas expands, driving the piston toward bdc, rotating the crankshaft and its attached weighted flywheel.

Half way down its first stroke the piston uncovers the exhaust outlet port and directed by the piston’s contoured head, exhaust gasses are partially ejected.

Induction and compression operations-stroke

2

The inlet port shown is a transfer port as it is open to both sides of the cylinder.

In the carburettor air and fuel are premixed and atomised. To improve the induction of fuel/air mixture into the crankcase, one-way valves (check valves, reed valves, or rotary valves) may be used in the intake port to allow the fuel air charge to get into the crankcase quickly, but prevent it leaking back out.

As the piston descends, the inlet port experiences a suction that inducts the fuel/air charge around the crankcase, in the process depositing a film of oil on the moving surfaces. Once past bdc and rising on its second stroke the piston pushes the charge up through the transfer port into the cylinder. This flow of the fuel/air charge into the cylinder forces any remaining exhaust out of the cylinder, a process called scavenging. Lastly, as the piston covers the inlet port, the fuel/air charge is compressed ready for the next power operation (ignition).

Valve and port diesel two stroke engines

Power (exhaust and induction) operations-stroke

1

Just before tdc the piston is positioned above the inlet port and the

exhaust valve is closed, so sealing the cylinder and its pressurised and heated

air. The crankshaft driven timing synchronises the injector to release a spray

of atomised fuel that explodes

instantly on mixing with the super heated air.

As the piston passes tdc, the burning gas expands, driving the piston toward bdc, rotating the crankshaft and its attached weighted flywheel.

With the initial force of the expansion expended, three quarters of the way down its first stroke the exhaust valve opens and exhaust gasses begin to be ejected.

An instant later the piston exposes the inlet port and fresh air is sucked in, often under pressure from a blower (supercharger or scavenger blower). This rush of fresh air further pushes the exhaust towards the outlet valve (scavenging).

Compression (exhaust and induction)

operations-stroke 2

After the piston passes bdc to begin the second stroke the fresh air compression completes the displacement of any remaining exhaust.

A quarter the way up the second stroke the piston covers the inlet port and next the exhaust valve closes. Now the air is fully compressed in the sealed cylinder ready for the next explosion.

Scavenging

Removal all burnt gases from the cylinder and replenishment with fresh charge (scavenging) is necessary to maintain the power and efficiency of the engine. The rapid operation of two strokes causes a flow of fresh air buffering against exhaust gasses to eject them. Improving the flow by careful design and a blower improves the scavenging efficiency. The cross flow type scavenging shown above uses a piston head profile directed towards the exhaust. Looped scavenging has inlets and outlets on the same side of the cylinder. Uniflow scavenging is arranged so the gasses all move centrally in the same direction towards the cylinder head outlet.

Engine designs

with transfer inlet ports positioned evenly around the cylinder improve

scavenging by allowing air to enter uniformly and push the exhaust towards the

exhaust valve.

Air, blowers and after-coolers

Small engines

are naturally aspirated purely by the suction created during the downward

stroke of the piston. However more complex engines use additional blowers to force

air into the cylinders and so increase their power and efficiency. Blowers may

be the supercharger or turbocharger type.

Superchargers

are driven directly by the engine and geared spin at up to twice the engine

speed. A stream of air from a supercharger can also partially cool the hot

running two-stroke.

Turbochargers

are driven by a turbine which is powered by the engine exhaust and may spin at

up to 100,000 r.p.m.

Balance and lubrication is critical. At high speed turbo vanes reach

high temperatures from the exhaust’s blast of flame. If the engine is instantly

shut down from high speed operation the rapidly spinning turbo will run-on for

a substantial time after the engine driven lubricating system has stopped. The heat

from the turbo vanes will conduct into the bearings with consequent damage. To

prevent these problems, hot engines should be allowed to idle for about 5 to 15

minutes before they are switched off, to allow the engine and turbo to cool

down.

Turbochargers also

heat the inducted air by compression. An after-cooler may be fitted to cool and

increase the density the air (providing more oxygen per unit of volume) before

it enters the engine, so increasing efficiency and cool running.

1.4 Timing – valves, injection and ignition

Diesel engines

Timing methods vary widely in different engine designs, but all must be set exactly as even a small timing error can stop the engine or seriously damage it. Injection, and the opening and closing of the valves, is accurately timed in relation to the position of the piston, by the gear or chain drive from the crankshaft to the camshaft. The meshed teeth of the gears ensure that injection and valve operations occur at the correct point of each work cycle. At speed engines work cycles occur so rapidly that valve and injection has to be initiated prematurely to counter the miniscule delay in actuating mechanism.

Four stroke engines have twice as many teeth on the camshaft gear (or sprocket) as there are on the crankshaft gear. This means the camshaft runs at half the speed of the crankshaft. The camshaft turns (injection and valves operate) only once for every two revolutions of the crankshaft.

With two stroke engines, injection occurs and the valves will open and close on each turn of the crankshaft. In two-stroke engines, the camshaft must run at the same speed as the crankshaft.

The specific opening and closing of the inlet and exhaust valves and the period of injection of the fuel can be taken from the engine manufacturers timing diagram. Examples are shown below:

Four stroke cycle diesel engine

The diagram below represents a Caterpillar turbo charged after cooled engine. The induction stroke commences when the inlet valve opens 10° before tdc when air is drawn into the cylinder as the piston moves down. The inlet valve closes 1° before bdc. The air is now trapped in the cylinder and as the piston rises on the compression stroke, the air is compressed. As the air is compressed, it rises in temperature. When the piston reaches 19° before tdc, the injection of fuel commences and continues until 73° after tdc.

The heat in the compressed air ignites the fuel and combustion takes place. The gases expand forcing the piston down on the power stroke.

The exhaust valves opens at 26° before bdc and the exhaust gases are discharged as the piston rises on the exhaust stroke. Most of the exhaust gases have been discharged as the piston nears tdc. However, at 10° before tdc, the inlet valve opens and air enters the cylinder and helps discharge any remaining exhaust gases until the exhaust valve closes at 3° after tdc. The whole cycle is then repeated.

Both the exhaust valve and inlet valve are open from 10° before tdc to 3° after tdc, an overlap of 13°. This is referred to as “valve overlap” and ensures that all the exhaust gases are discharged from the cylinder and the cylinder receives a fresh charge of air to make it more efficient when combustion next takes place.

Therefore there is one power stroke for every cycle or two revolutions of the crankshaft.

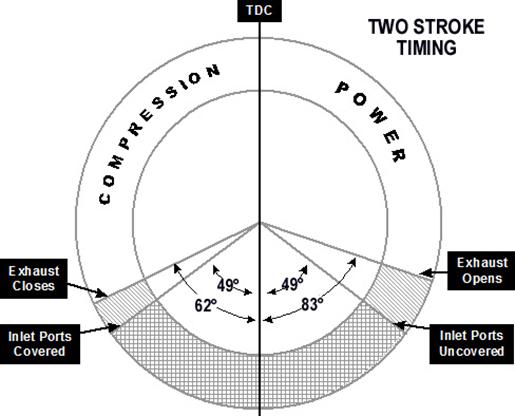

Two stroke cycle diesel engine

The two strokes of power followed by compression are required to complete one cycle. The events of injection, combustion, expansion and compression of the gases takes place as the four stroke engine, but the exhaust of the burnt gases and the induction of air take place at the bottom of its stroke, this being a chief difference between the two stroke cycle and the four stroke cycle.

There are variations in two stroke cycle engines. The

type described here is the most common to be found in marine engines. It has

inlet ports and exhaust valves. The

inlet holes or ports are in the lower section of the cylinder liner wall.

The piston uncovers the inlet ports as

it moves down the cylinder. The piston covers the inlet ports as it moves up

the cylinder. This action has the same effect as a valve opening and closing. An

engine driven scavenge blower is fitted and the incoming air is blown into the

cylinder through the inlet ports when they are uncovered by the piston.

The above timing

diagram represents a Detroit Diesel turbo charged inter cooled engine. Induction

commences at 49° before bdc when the piston has

uncovered the inlet ports. Air is forced into the cylinder by the scavenge

blower as the piston moves down to bdc and back up

again until it covers the inlet ports at 49° after bdc.

As the piston

rises, the exhaust valve closes at 62° after bdc. The

air is now trapped in the cylinder and as the piston rises the air is

compressed and rises in temperature.

Fuel is injected

before tdc and continues after tdc.

Detroit Diesel do not specify the period of injection as this will vary

depending upon the engine speed, the load and the size of the injectors. The

camshaft contains the exhaust valve cams as well as the unit injector cams.

Therefore, if the exhaust valve timing is correct, the unit injector timing

will be correct providing the injector follower is adjusted to a definite

height in relation to the unit injector. A special gauge is supplied to set

this height.

The heat in the

compressed air ignites the fuel and combustion takes place. The gases expand

forcing the piston down on the power stroke.

The exhaust

valve opens at 83° before bdc allowing the burned

gases to escape into the exhaust manifold. However, at 49° before bdc, the inlet ports are uncovered by the piston and air

enters the cylinder and helps discharge any remaining exhaust gases until the

exhaust valve closes at 62° after bdc. The whole

cycle is then repeated.

There is one

power stroke for every revolution of the crankshaft.

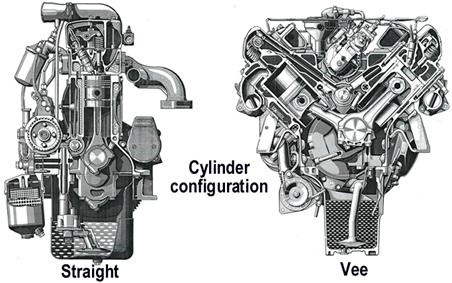

Most marine engines have several cylinders for more power and smoothness. (The cylinders are identified by numbering them in order, from the front of the crankshaft (inboard end) to the back (propeller shaft end).

Above, the cylinders are numbered 1- 4. The

timing assembly consist of rockers 5, valves 6, push rod 7, cams 8, camshaft 9

and timing gear 10. The crankshaft is 11 and the flywheel 12.

In engines with several cylinders, the

cylinders are designed to fire one after the other, to increase the smooth

delivery of power. They do not fire in consecutive order

(1,2,3,4,5,6,7,8), as this would have

the effect of twisting one end of the crankshaft while the other end tries to

catch up. Instead, cylinders are

designed to fire, first at one end of the engine, then at the other. In this way, the power thrust is more evenly

balanced on each end of the crankshaft.

Typical firing orders for internal

combustion engines are:

Four

cylinder engines 1,3,4,2 (sometimes 1,2,4,3)

Six

cylinder engines 1,5,3,6,2,4 (or 1,3,5,6,4,2)

Vee

eight cylinder engines 1,5,4,8,6,3,7,2

is most common

The cylinders are usually configured in a

straight line along the centre of the block, being called straight. Alternately they can be configured in the vee or v arrangement as shown below fitting greater power potential in a

more compact space.

Some auto engines arrange the cylinders in a

horizontal plane with pairs of pistons punching out to opposite sides of the

block, hence its name the boxer

engine, which provides balanced performance.

Valve timing

Valve timing is

the critical relationship between the position of the crankshaft and the

opening and closing of the inlet valves and exhaust valves. The valve train is

geared or has a chain drive with sprockets on the camshaft and crankshaft. Any

slight variation from the correct timing setting will result in loss of power

and overheating. Any large variation and the engine will not start.

To accurately

check the valve timing, it will be necessary to remove the timing cover to gain

access to the timing gears. The gears or sprockets are fitted to the crankshaft

and camshaft by keys so they can only be fitted in one position. However, they

can be incorrectly lined up to each other.

The operators

manual will indicate what the timing marks look like and in the case of chains,

what the sprockets should line up with. Typical lining up marks for gears are

shown below:

When timing has

been found to be correct, the tappet clearances (also referred to as valve

lash) should be checked. Whenever the cylinder head is overhauled, the valves

are reconditioned or replaced, or the valve operating mechanism is replaced or

disturbed in any way, the tappet clearance must be adjusted - also when the

cylinder head has been re-tightened after the initial run in period.

As the valve and

valve operating gear heats up in service, the clearance between the rocker arm

and the valve stem decreases. If insufficient clearance is allowed, the valve

will be prevented from seating. The correct clearance will be specified by in

the operator’s manual. Some manufacturers state clearances for an engine is at

its normal operating temperature, others when the engine is cold, while some

give both.

Clearances will

vary as much as 0.128 mm (0.005”) between a cold and the normal operating

temperature of an engine. Usually, an exhaust valve will have a greater

clearance than an inlet valve because of their different operating

temperatures.

Too much

clearance will cause excessive wear, noisy operation and altered valve timing,

that is, late opening and early closing. If the clearance is insufficient and

the valve does not seat properly, it will result in loss of compression through

valve leakage, burning and eroding of the valve and seat and general overheating.

In the extreme,

it is possible that the piston could strike the valve resulting in a bent valve

stem, damaged piston or worse if the valve or piston should break.

If the valve operating mechanism is

disturbed in any way and the engine is cold, but only a hot tappet clearance is

given, the tappet clearance must be checked. If required, further adjust when

the engine is at its normal operating temperature.

The most common

form of adjustment for tappet clearance is by means of a screw and lock nut

located in one end of the rocker arm. The clearance is measured by means of a

feeler gauge between the valve stem and rocker arm when the valve is in

the fully closed

position. This is usually done when the piston, under the valve being adjusted,

is on top dead centre at the end of the compression stroke.

An easy way to identify the above is as

follows:

On a six

cylinder engine with a firing order of 1 5 3 6 2 4, turn the engine over in the

direction of rotation. When the inlet valve and exhaust valves are rocking on

number 6 cylinder (i.e. the piston finishing its exhaust stroke and starting

its induction stroke) adjust the inlet and exhaust valve clearances on number 1

cylinder which will just be completing its compression stroke and commencing

its power stroke.

On the

crankshaft, the bottom end journals on numbers 1 and 6 are 180° to each other,

2 and 5 are 180° to each other, and 3 and 4 are 180° to each other.

What you are

doing is adjusting number 1 tappets while number 6 is rocking, then adjust

number 5 because it is the next one in the firing order to be on top dead

centre while number 2 is rocking, adjust number 3 while number 4 is rocking,

adjust number 6 while number 1 is rocking, adjust number 2 while number 5 is

rocking, and adjust number 4 while number 3 is rocking.

On a Detroit

Diesel, the exhaust valve/s can be adjusted on the cylinder on which the unit

injector follower is fully depressed. This means that fuel injection is taking

place so it is at the end of the compression stroke and the beginning of the

power stroke.

Timing a fuel injection pump

Early injection - If the injection occurs too early on the

compression stroke, it will result in high peak pressures. This will subject the engine to unsafe

stresses caused by the tendency of the pressure to reverse the rotation of the

engine and evidence by excessive detonation which is known as diesel knock.

Late injection - Retarded injection or late burning gives

incomplete combustion causing too low a power output and overheating.

Timing

instructions

It will be

necessary to follow the manufacturer’s instructions in the owner’s manual to

time the fuel pump to the engine as different methods are employed.

Timing principle - fuel injection commences on the compression

stroke just before top dead centre. With a four stroke, the piston also comes

up to top dead centre on the exhaust stroke. Make sure it is on the compression

stroke. As with timing inlet and exhaust

valves, the fuel injection pump must be timed to inject fuel at the correct

angle on the compression stroke. This means that the gear driven shaft to the

pump must also be lined up in the gear wheel train, otherwise, difficulty might

be experienced in lining up the holes in the drive coupling.

Timing engine to pump -The flywheel is usually marked with a tdc and with an injection mark that is before the tdc mark when turning the engine over in the direction of

rotation. Turn the engine over in the direction of rotation until its number 1

cylinder is on the compression stroke and the injection mark is lined up. The

fuel

injection pump

must also be lined up on number 1 element or port at the commencement of

injection. The owner’s manual will identify the position of the lining up marks

as brands of pumps differ. When the lining up marks on the pump meet the drive

couplings can be bolted together.

Alternative method of timing - Some manufacturers make provision for

locking the fuel injector pump shaft at a position corresponding to tdc for number 1 cylinder. A further pin is then located in

a hole in the camshaft timing gear that is tdc for

number 1 cylinder. The drive couplings can then be bolted together and the pins

removed.

As the pin is

located in a hole in the camshaft, it can only be on the compression stroke on

a four stroke engine.

Checking the timing of a fuel pump -The timing may be checked as follows:

Remove the

delivery valve and spring from number 1 element in the fuel injection pump. Open

the throttle to the full position. (If the throttle is left at the stop

position, the slot in the plunger will be in line with the spill port and no

fuel will be delivered.)

Rotate the

engine in its operating direction until number 1 cylinder is on the compression

stroke. Keep rotating the engine slowly and when the mark on the flywheel, indicating

the start of injection is lined up with the timing indicator mark, fuel will

immediately start to rise from where the delivery valve was removed. (This will mean the top of the plunger has

just covered the inlet and spill ports and injection is starting). If fuel

starts to rise before or after the timing marks are in line, the fuel pump

timing is out and will have to be adjusted.

Detroit Diesel unit injector - On a Detroit Diesel, the cam that actuates

the unit injector is on the same shaft as the cams for the exhaust valves. If

the exhaust valves are correctly timed, that is they open and close at the

correct angles, then the unit injector timing must be correct. It is then only

a matter of adjusting the unit injector follower to get the correct height in

relation to the unit injector body. A special gauge is supplied for this

purpose.

Cummins PT injector - On the Cummins PT system, it is only a

matter of setting the clearance between the rocker arm and the injector.

Petrol engines

Similar timing principles and mechanisms are used in petrol engines, with the fundamental differences that a pre-mixed fuel/air charge is introduced to the cylinder during the induction stroke and that the ignition requires an electrically driven spark to initiate the power stroke.

Smaller engines may use the magneto to produce the high voltage required for an electrical spark to arc across the spark plug gap. More complex engines will use a coil, distributor and contact breakers (or points).

The

magneto

A magneto

is an electrical generator using wire coils and magnets to produce alternating

current. It produces pulses of high voltage to activate the spark plugs of

small petrol driven engines such as light weight outboard motors and lawn mowers.

The shuttle magneto variation spins a wire

coil on its flywheel between the poles of a magnet whereas the inductor

magneto spins the magnet around a static wire coil.

The ignition

timing relies on a cam on the drive

shaft openning the

points (contact breakers) momentary interrupting the current and collapsing

a coil’s electromagnetic field. This induces a voltage across the coil, which

in turn supplies the energy for the spark plug firing. The size of the points’

gap opening can be adjusted to the manufacture’s recommendation. Its position

in relation to the cam can be adjusted to fine tune the ignition timing.

To prevent high

voltage arcing at the point’s contacts, leading to rapid decay, a capacitor (an electrical storage and

smoothing device) is placed across the points to absorb the energy burst. (Capacitors were previously called condensers, are built from two films of electrical conductors

separated by a film of electrical insulator).

The system is rarely

used for vehicles or vessels that have electrical accessories, except for aero

piston engines where simplicity and reliability are of advantage. The magneto

is not used to charge batteries in marine systems but in old outboard motors

may be wired to power an emergency light.

The battery, coil and distributor

More

complex multi cylinder engines will use an electrical system energised by a

battery bank that is kept charged by an alternator. This system induces a voltage across the coil,

which in turn supplies the energy for spark plug firing.

A crank driven distributor shaft revolves in a

cylindrical distributor body. The

shaft drives a cam that opens the points momentary

interrupting the current and collapsing the coil’s electromagnetic field. To

prevent high voltage arcing at the point’s contacts, leading to rapid decay, a capacitor (an electrical storage and

smoothing device) is placed across the points to absorb the energy burst. (Capacitors, previously called condensers, are built from two films of

electrical conductors separated by a film of electrical insulator).

The perimeter

of the distributor’s cap has contact

points individually connecting to each spark plug by a high tension lead. (Don’t touch them during running or you will

receive a high energy electrical shock!) As the distributor shaft rotates, the rotor arm fitted to its head brushes

past each contact point in turn to distribute the electrical energy to each

spark plug in the correct order and time.

The size of the

points’ gap opening can be adjusted to the manufacture’s recommendation. In

order to fine tune the ignition timing, its position in relation to the cam can

be adjusted by rotating the distributor body around the distributor shaft.

Further information on outboard engine petrol ignition is provided in Chapter 8.

1.5 Air supply

Turbo charging

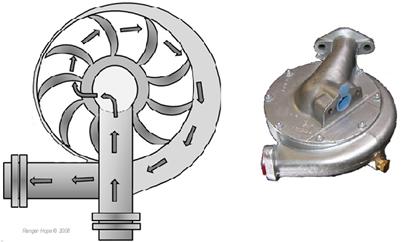

A turbo charger (sometimes called a turbo

blower) can be fitted to both two and four stroke engines to increase the

volumetric efficiency and thus their power output. It uses the force of the

expelled exhaust gasses passing through a turbine to drive a rotor blowing air

into the air inlet.

Advantages

- The advantage of a turbo charger is that

fuel consumption is lower than that of a normally aspirated engine of the same

power output. In addition, the turbo charger utilises the exhaust gases of the

engine so no additional power from the engine is required to drive it.

The turbo

charger inducts a larger mass of air into the cylinder to that of a same cubic

capacity normally aspirated engine. This allows for a proportional increase in

the amount of fuel that can be injected and burnt in the cylinder thereby

providing an increase in the power output of the engine.

Components

of a turbocharger

A cut away of a

turbocharger’s components are shown below:

Rotor assembly - It has a rotor

shaft which has exhaust gas turbine blades on one end and air compressor blades

on the other end.

Casings - The exhaust gas

turbine blades are housed in a casing which is attached to the exhaust manifold

and to the exhaust pipe. Some casings are fresh water cooled to minimise the

heat radiated out into the engine space. This allows for a cooler engine space,

cooler air entering the engine air intake and therefore more power again. A

nozzle ring is fitted inside the casing to direct the flow of exhaust gases to

the turbine blades.

The air compressor blades are also housed in a casing which has an air

cleaner on the intake side and is connected to the intake manifold on the

discharge side. Where an engine is after cooled, the discharge side is

connected to the after cooler which is then connected to the intake manifold. Both

the above casings are attached to a centre casing which contains the bearings,

seals and method of lubrication.

Bearings and lubrication - The shaft may rotate in white metal bearings which can be lubricated from the engine driven oil pump. This method of lubrication also allows the oil to remove some of the heat in the turbo charger. One bearing locates the shaft and takes the small residual thrust, the other bearing allows the shaft to move longitudinally to accommodate the differential thermal expansion of casings and shafting.

Alternatively, the smaller turbo chargers usually incorporate a ball

bearing for positioning at the compressor end and a roller bearing to

accommodate axial expansion at the turbine end of the rotor shaft. The bearings

may have their own reservoir which forms part of the turbo charger. These

reservoirs usually have round oil level sight glasses with two horizontal lines

marked to indicate the high and low levels. Seals are fitted to retain the oil.

Operation

of the turbo charger on a diesel engine

In a four stroke

engine, exhaust gases flow from each cylinder into the exhaust manifold and

then past the turbine blades of the turbo charger. With the engine running at

full speed, the turbo charger can obtain speeds up to 100,000 revolutions per

minute (rpm). The air compressor blades will revolve at the same speed. Air is

drawn through the air cleaner and forced under pressure into the intake

manifold. When the inlet valve opens on the induction stroke, with the piston

descending in its cylinder, air is forced into the cylinder. It is necessary to

reduce the turbo charger speed in stages or slowly for two reasons:

If the engine

speed is reduced from full engine speed to stop quickly and the bearings of the

turbo charger are lubricated by the main engine driven lubricating oil pump,

the engine, on stopping, will cease to supply the lubricating oil to the turbo

charger bearings. Because of its high speed, it will take some time for the

turbo charger to come to rest and the bearings could be damaged. The exhaust

gas side of the turbo charger operates at a very high temperature. It is

preferable to reduce the temperature gradually rather than quickly to prevent

unequal contraction of the turbo charger parts as it slows down.

Monitoring

the performance

Normally, as

part of the purchase of a new engine, the engine distributor or dealer will do

an installation and pre-run check. The following will be recorded:

The speed of the turbo charger at a

nominated engine speed.

Air flow in.

Air flow out.

Air pressure after the compressor blades.

Exhaust gas flow

The flow of air

going into the turbo charger is important. The air is taken from the engine

room so sufficient ventilation to the engine room is required to ensure there

is enough for the engine as well as cooling the engine room. The exhaust gas

flow is also important. It ensures the installation of the exhaust piping is

within limits and not restricting the performance of the engine. As the above

is recorded, checks can always be carried out and readings compared with the

initial ones.

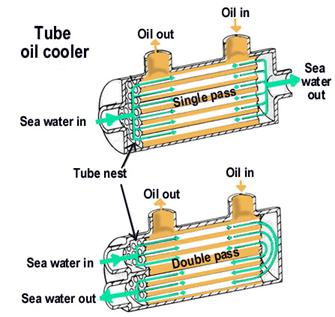

After coolers (charge air coolers)

An after cooler

is also called an inter cooler or a charge air cooler. An after cooler is

fitted where an engine is turbo charged, however it is not necessary to fit

one. Therefore an engine can be turbo charged or can be turbo charged and after

cooled.

The reduction in

air temperature will increase the density of the inlet air resulting in more

air entering the cylinder. More fuel can then be injected and burnt, giving

increased power.

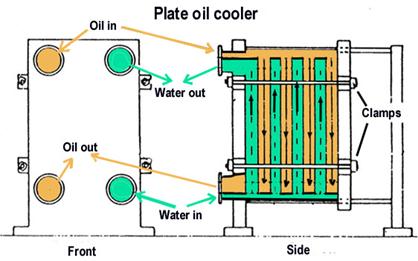

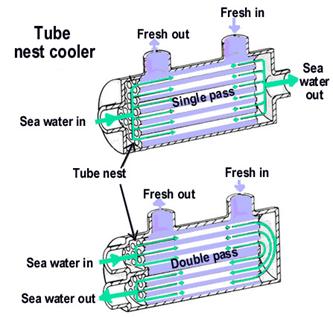

The after cooler

is fitted between the air compressor side of the turbo charger and the air

intake manifold on the engine. In the after cooler, air passes over the outside

of the tubes while the engine cooling water or sea water passes through the

tubes usually in the opposite direction (contra flow). Fin plates are attached

to the outside

of the tubes to

increase the surface area for the air, thereby giving a better transfer of

heat.

Maintenance

Sea water

flowing through the tubes will tend to leave deposits in less time that if

fresh water was used. The end covers can be removed and a wire brush pushed and

pulled through the tubes. If the scale is not removed by the brush, the tube nest

will have to be chemically cleaned.

On the air side,

usually no maintenance is required if the air cleaner is doing its job and the

filter is changed regularly. A leaking tube will cause the cooling water to

pass into the air side. Depending on the design, the air may enter at the

bottom and leave at the top to prevent water carrying over with the air. A

drain cock is fitted at the bottom.

As the air

passes through the after cooler, its temperature may be reduced until it is

below the saturation temperature. Heavy condensation of water vapour may then

follow, this water being carried into the engine. If this is a problem, a water

separator can be mounted between the after cooler and the air inlet manifold.

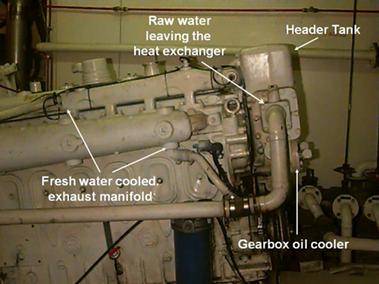

1.5 Engine protection - devices

In best practice vessels of the 25 metres class (80 tonne) will be fitted with an audible warning device to indicate a dangerous condition associated with:

engine lubricating oil pressure;

engine jacket cooling water outlet

temperature; and

engine gear box lubricating oil pressure.

It should be noted that these protection devices give off an audible warning only and do not shut down the engine. Automatically shutting down an engine without any warning could have dangerous consequences and result in collision, grounding, or the loss of the vessel.

The alarm system may have a switch that must be turned on manually to put the system into operation. The danger of this system is the operator may forget to activate the system allowing the engine to run in an unprotected mode. It is preferable that there be no alarm switch. If there is an alarm switch, it is good practice to switch it on before starting the engine. It will sound until the engine is started and the minimum oil pressure registers. Similarly, it should not be switched off until the engine is stopped and the alarm sounds. This procedure also checks that the alarm is operational.

The gear box low lubricating oil pressure alarm operates in the same fashion as the engine low oil pressure alarm.

Low

oil pressure alarm

The oil pressure alarm consists of a pressure switch fitted to the pressure side of the lubricating oil system, usually into an oil gallery. The oil pressure acts on a diaphragm and spring which open the contacts in a micro switch. When the spring

pressure is greater than the oil pressure, the contacts will close and sound the audible alarm.

If an alarm switch is fitted, switch it on. When the engine is started, the oil pressure switch opens when the oil pressure reaches approximately 69 kPa (10 psi) and the alarm will cease to sound.

Likewise, if the oil pressure drops below the setting of 69 kPa (10 psi), the oil pressure switch will close the circuit and sound the audible alarm.

The alarm will continue to sound until the engine is stopped or the alarm switch, if fitted, is switched off.

High

temperature fresh water alarm

The high temperature fresh water alarm consists of a thermo switch. It has a bi-metal probe that activates contacts in a micro switch. It is installed in the side of the thermostat housing. When the engine is started and running at normal operating temperature, the contacts in the switch will be open. Should the engine coolant exceed 96° C (+ or - 3°) the water temperature switch will close the electrical circuit and sound the audible alarm and/or indicator light. The gear box low lubricating oil pressure alarm operates in the same fashion as the engine low oil pressure alarm.

A Detroit Diesel engine has an additional sensor fitted for the protection of their engines. In addition, advising the engineer of a slight loss of coolant, non circulation of the coolant or failure of the sea water cooling action, the alarm will also sound if there is a large loss of coolant.

A big and sudden loss in coolant may reduce the coolant level to below the probe in the thermostat housing. As the water is now not circulating over this probe, it will not detect the rise in temperature of the coolant. An additional sensor is fitted into the exhaust manifold outlet to detect the rise in temperature due to overheating.

The water temperature switch consists of a temperature-sensing valve and a micro-switch. The valve contacts a copper plug (heat probe) which extends into the exhaust manifold outlet. Engine coolant is directed over the power element of the valve and if the water temperature exceed its setting, the valve will close the contacts in the micro-switch thus closing the circuit and sounding the audible alarm. If a loss of coolant occurs, the heat of the exhaust gases will be transmitted through the copper plug to the temperature-sensing valve thus closing the circuit and sounding the audible alarm.

Emergency stop device

Numerous engines are fitted with a manually operated emergency engine shut down device, mounted in the air inlet housing, to stop the engine in the event an abnormal condition arises. If the engine continues to run after the engine throttle is placed in the no fuel position, or if combustible liquids or gases are accidentally introduced into the combustion chamber causing over speeding of the engine, the shut down device will prevent damage to the engine by cutting off the air supply stopping the engine.

The shut down device consists of an air shut off valve (flap) mounted in the air inlet housing which is retained in the open position by a latch. A cable assembly is used to remotely trip the latch. The shut off valve must be manually reset on the latch for restarting the engine after the malfunction has been rectified.

Chapter 2: Fuel storage and handling

2.1 Fuel storage and survey compliance

The standards

Compliance

To ensure safe vessels seafaring nations developed Classification Societies to keep registers (lists of approved safe vessels). Those organisations still determine rules (specifications) and conduct surveys for construction, equipment and maintenance for each vessel class according to its trade and sea area of operations.

American Bureau of Shipping AB Det Norske Veritas NV

Lloyds Register of Shipping LR Germanischer

Lloyd GL

Bureau Veritas

Nippon Kaiji Kyoka

China

Classification Society

For new vessels, a classification society or

survey authority will approve the specifications for design plans and check the

quality of materials and workmanship of all stages of the construction process

at the Initial Survey. To ensure

maintenance to the survey standards, regular ongoing inspections are scheduled,

called Periodic Surveys. These approved

specifications, the World’s best practice,

are supported in Australian legislation, regulated by the Australian Maritime

Safety Authority (AMSA).

The Australia domestic commercial vessel

fleet (under 80 mtrs long and under 200 nm offshore)

is transitioning from State survey authorities operating the Uniform Shipping Laws specifications

(USL code) to a National survey authority (AMSA Domestic Vessel Division)

operating the newer National Standards

for Commercial Vessels (NSCV). While drawing from the USL code, the NSCV

updates and provides the flexibility required by developers and operators. It

retains a prescriptive approach to compliance in its deemed to satisfy standards (standards

that shall be met) but also provides

a flexibility with performance based equivalent

solutions” (that can be proven to be as effective as those deemed to

satisfy).

Vessel survey

compliance will depend not only on its operations (trade and plying limits) but

on its survey authority their grandfathering exemptions from past survey

regimes or allowances from current equivalent solutions. In short, to confirm

your vessel’s survey compliance you will need to contact its Survey Authority.

However, some

features that are common in all domestic commercial vessels fuel system

installations that meet best practice in structural integrity, fire control,

environmental management and stability.

NSCV Survey

Due to the

greater explosive risk posed by petrol, inboard installations must be diesel

fuelled though petrol is

allowed for vessels fitted with outboards. Some special purpose petrol inboards

may be approved for petrol inboards (high powered wake and ski boats) where

risk mitigation includes starter interlocked engine room purging blower and

fuel management procedure.

NSCV surveys frequency is determined by risk level. Risk factors include age, attributes, operational area and nature, incident history of vessel class and performance of the operator. Greater risk category vessels include:

Class 1A, 2A, and 3A vessels (unlimited sea

areas);

Class 1 > 35m in measured length;

Class 1B/1C that berth one or more pax or berth >12 persons or carry more >36 pax;

Class 1D/1E that berth one or more pax or berth >12 persons or carry >75 pax;

Class 2B vessels > 35m in measured length

(workboats to 200nm offshore)

Class 2 tankers, dangerous goods carriers or

tug boats.

Survey

cycles

The periodic survey inspections of a vessel are

arranged in survey cycles of 5 years (inspections at 1, 2, 3, 4 and 5 years). These

periodic surveys are not intended to confirm the vessel’s compliance with every

requirement but to identify and verify the continued existence and

functionality including trialling machinery and its fuel systems.

1 yearly inspections -

for all vessels would include all pipe arrangements.

5 yearly inspections - for vessels 35 metres and over of deep tanks and double bottom tanks used exclusively for fuel oil, to be examined externally and tested to a head sufficient to give the maximum pressure that can be experienced in service.

One deep tank and one double bottom tank used exclusively for fuel oil to be surveyed internally every 5 years starting when the vessel is 10 years old.

10 yearly inspections – vessel hull thickness and examine larger fuel tanks internally

The term to examine

means a process that commences with a visual inspection that identifies the

evidence of damage, deterioration and/or modification (may require dismantling

if deficiencies are found).

The term to test

means the physical gauging of properties with the objective of ascertaining

continued readiness to function, condition or conformance with standards. E.g.

hammer tests, ultrasonic thickness measurements, oil analysis, starting of

machinery, turning of handles

The term to trial

means a specific type of rest of a system or component to ascertain functional

performance and/or compliance with applicable standards. E.g. machinery trials,

emergency generator trials, steering trials, fire hydrant appliance trials,

anchoring trials, evacuation trials.

The term to verify means to

ensure that an item exists and is as per the plan, meets or has been declared

as meeting an applicable standard by a an Authority.

Survey should not be confused with maintenance. A responsible owner will have a maintenance program to open up, inspect and repair at lesser intervals than required by the survey authority. Surveyors have the discretion to survey fuel oil tanks of the vessel not due for survey if he considers such action is warranted.

Fuel

storage components

Fuel

tanks

Fuel

tanks for storage of the fuel or for daily service tanks may form part of the

hull structure, be free standing and substantially constructed of carbon steel,

stainless steel, copper or marine grade aluminium. Fuel

storage arrangements on board are largely dependent on the intended service of

the vessel and location of refuelling stations within the area of operation of

the vessel. Typical arrangements include:

Short

distance -Tanks

port and starboard within the machinery space. These may be free standing or

form part of the hull structure plus a smaller tank for direct supply to the

main engine and generator engines. Fuel from the larger tanks is transferred to

the smaller tank as required.

Medium

distance - A

bunker or deep tank divided into port and starboard tanks forward of the

machinery space the aft bulkhead of the tank being the machinery space forward

bulkhead, with a small tank as for short distance, or:

Two small tanks both capable of supplying

the main engine and generator engines, each with independent lines to the main

and generator engines. The tanks would be used alternately.

Long

distance - as

for medium, but with the addition of a double bottom fuel tank/s.

Multiple tanks can have a cross over valve

fitted to either the fuel supply or return lines enabling the engines to be run

from either tank or in the event of contamination, to isolate an offending

tank. Care must be taken if redirecting a fuel return line to one tank only as

this effective fuel transfer can be rapid and may affect the vessels stability

or even overflow the tank.

Some vessels may have two day tanks, thus

the fuel return from the engines injectors should be changed over when the

delivery is changed. Similarly, it is wise to close cross over fuel supply

lines when refuelling from a high pressure fuel pump. The thrust of fuel

entering the port tank filler pipe may depress the fuel in the tank and even

force fuel up to overflow the starboard tank. The reverse will occur when the

filling stops as fuel from the starboard tank can surge back to spill out from

the port filler pipe.

Double bottom and void tank tops are prone

to corrosion but must be more regularly inspected. A weep of water entering a

double bottom tank through damage to the outer hull will suddenly become a

flood if the tank’s resisting internal air pressure fails due to the tank top

watertight seal corroding away.

Tank

components

Baffles

–

Perforated baffles (or not continuous baffles) are fitted inside the tank to

allow limited liquid movement but minimise free surface area effects of liquids

sloshing around as the vessel moves. Normally spaced not more than 1 m apart,

those fitted longitudinally will reduce free surface caused by the vessel

rolling and transverse baffles will reduce that caused by the vessel pitching.

Breathers-

Fuel tanks, containing flammable liquids, are required to be vented to

atmosphere (not into the vessel). This breather pipe will terminate in a gooseneck

or swan neck (a cranked pipe), which limits rain and spray from entering. If

the vent pipe is greater than 18 mm in diameter, the outlet is fitted with a

wire gauze for a flame trap.

Filler

pipes-

Filler pipes are arranged so spillage will not enter the vessel. The inlet or

delivery end of the pipe is located outside the vessel and will have a valve

and fuel tight cap. The pipe between the deck and the top of the tank may be

flexible, but must be reinforced and secured with twin corrosion resistant clips.

Fuel

pipes - Generally

unarmoured plastic or rubber flexible hose is not compliant.

Inspection

port -

The top or bottom of tanks, where water and condensation accumulate, are prone

to corrosion and need regular inspection. The bottom of the sounding pipe can

corrode or even jam the sounding device. Consequently fuel tanks of more than

800 litres capacity require opening up and inspecting at periods of not more

than 12 years through a manhole or inspection port. A larger tank may also have

modified vent pipes or fitted purging (by inert gas) pipes to ensure tanks are

evacuated of flammable gasses before opening up. The precautions of entering a

confined space must be applied.

Pumps

- are

used for transferring fuel between tanks. There may be a separate pump to

supply fuel at pressure to the engines. Stop valves are to be provided on the

suction and delivery sides of power operated pumps.

If the closed discharge pressure exceeds the

maximum design pressure of the system a relief valve discharging back to the

suction side of the pump shall be fitted.

Pumps located below decks shall be provided

with a means to stop the pump from a safe place outside the space.

Save

all –

Tanks that are fitted above machinery must have drip trays (savealls)

fitted to prevent leaks onto moving parts. Fillers, engines and gearboxes are

similarly fitted to stop oil reaching the bilge. Save alls also need drainage

arrangements.

Shut

off valves -

All fuel supply lines must have a means to be provided outside a propulsion

machinery space, (in an accessible position not likely to be isolated by a fire

in the space), to shut off the fuel to the main and auxiliary engines by means

of a fire safe valve or cock. In practice this means that a valve or cock

required to be fitted to each tank outlet can be operated from a safe position

outside the space by means of an extended spindle, or some other method of

remote operation. Any fuel

transfer or a cargo oil pump which is

located below deck in a machinery space shall be provided with a means to stop

the pump from both inside and outside the space.

Sludge

box & drain -

Sediment contaminants of water, algae and debris will gather at the tank bottom

where they must be periodically removed through a self closing sludge valve. In

the event of the tank rupture or for periodic inspections, all fuel tanks which

are not double bottoms must be fitted with a method of draining them into

another storage tank (not the bilge).

Sounding

and sight gauges -

Float fuel gauges are unreliable due to a vessel’s changing trim, so checking

the contents of the tank can utilise poking a calibrated stick (sounding rod)

down the filler pipe until it hits the bottom of the tank and reading off the

height of fuel that coats the retrieved rod (sounding the tank). An alternative

is to read the dry end of the retrieved rod showing the airspace above the fuel

(an ullage).

If the tank’s pressed up capacity is known then its remaining fuel can be

calculated. Whether a filler pipe or a dedicated sounding pipe is fitted, at the

tank bottom a reinforcing striker plate is welded to prevent a hole being

eventually battered into the tank bottom.

An alternative measuring technique is a

transparent sight glass spanning top to bottom whose fuel level reflects that

of the main tank. This clear plastic/glass tube is more vulnerable to fire and

impact than the main steel tank, so survey regulations specify that a self

closing valve be fitted in case of rupture. Under no circumstances must these

valves be left open. A recent variation is a non ferrous sight gauge containing

a steel float whose height (and tank volume) can be determined by magnetic

sensors. Tanks may be fitted with an overflow pipe which leads to an overflow

tank or relief double bottom fuel tank. These overflows can be fitted with a

sight glass and audible alarm. When re-fuelling, a safety managed procedure

that utilises pollution and spill control devices must be operated to prevent

spillage or fire.

Petrol and diesel fuel systems are more

fully described in Chapter 3.

2.2 Fuel transfer pumps

Unless the vessel’s fuel tanks are

positioned above the level of the engine or a day tank is installed at

sufficient height, fuel cannot be gravity fed to the engine’s fuel injection

pump. To assist in drawing fuel from the tank/s a fuel transfer pump is fitted

between the tank/s and the fuel injection pump. Fuel transfer pumps are also called

transfer, lift or charge pumps.

Diaphragm

type transfer pump

The diaphragm type transfer pump is

mechanically driven by a special lobe on the camshaft. The lobe pushes against

the lever causing the diaphragm to be pulled down against a spring pressure,

creating a partial vacuum.

A first check valve opens and draws in fuel,

filling the chamber between the diaphragm and check valves. As the lever moves

off the lobe of the cam, the diaphragm spring pushes the diaphragm up, closing

the first check valve forcing fuel through a second check valve and into the

fuel pump. An external lever is provided to permit manual operation of the pump

for priming purposes.

The pump will deliver more fuel than is

required. The fuel not being used will build up pressure in the line between

the fuel pump and the fuel transfer pump causing the second check valve to

close. The downward movement of the diaphragm will allow more fuel to enter

through the first check valve into the chamber. The first check valve will

close and as the return spring cannot overcome the pressure in the line between

the fuel pump and the second check valve, the lever will be held off the cam

until more fuel is required.

This diaphragm pump could be attached to the

side of the fuel pump and actuated by a cam on the camshaft for the fuel pump.

Alternatively, it may be attached to the block and actuated by a cam on the

main camshaft.

Plunger type transfer pump

The plunger type fuel transfer pump is

mechanically driven by a dedicated lobe on the camshaft. This pushes against

the plunger in the fuel transfer pump to create the pumping action. Check

valves control the direction of fuel flow, and prevent fuel bleed back during

engine shut down.

As the high point on the cam lobe rotates

away from the fuel transfer pump, the spring forces the piston towards the

camshaft. The pressure of the fuel in the piston bore closes the first check

valve and opens a second check valve forcing fuel to the low pressure supply

line. As the piston moves, a third check valve opens and fuel is drawn into the

spring cavity.

As the high point of the cam lobe rotates

towards the fuel transfer pump, the plunger and piston are forced towards the

inlet. The pressure of the fuel on the spring side of the piston causes the

third check valve to close and first check valve to open, allowing the fuel in

the spring cavity to flow to the other side of the piston.

A second plunger allows manual priming and

bleeding of air from the system. When the plunger is depressed, the first check

valve prevents back flow forcing fuel through the second check valve. When the

plunger is released, the spring forces the plunger outward. This action creates

a suction that causes the second check valve to close and the fuel is drawn

through the open first and third check valves.

If the pump supplies more fuel than is

required, the fuel will build up the pressure in the line between the plunger

pump and the fuel pump. The pressure build up will hold the plunger stationary

against the plunger spring an away from the arm, effectively stopping pump

operation until more fuel is required.

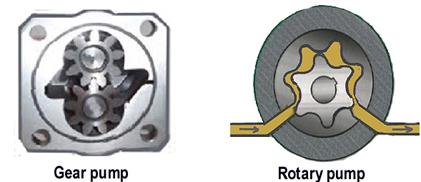

Gear

type transfer pump

This pump consists of two meshed gears in a

closely fitted housing with inlet and outlet ports opposite one another. One

gear is driven by the power source and in turn drives the other. As the gear

teeth separate and travel past the inlet port, a partial vacuum is formed. Fuel

entering the inlet port is carried to the outlet port in

pumping chambers formed between the gear

teeth and the housing. As the gear teeth mesh at the outlet there is no place

for the fuel to go but out.

Vane

type transfer pump

In the vane type pump, a slotted rotor

driven by a drive shaft rotates between closely fitted side plates, and inside

of an elliptical or circle shaped ring. Polished, hardened vanes slide in and

out of the rotor slots and follow the ring contour by centrifugal force.

Between succeeding vanes, pumping chambers are formed which carry oil from

inlet to the outlet. A partial vacuum is created at the inlet as the space

between the vanes open. Fuel is squeezed out of the outlet as the pumping

chamber size decreases.

2.3 Fuel handling

Refuelling

management

Fuel

arrangements must take into account its highly flammable nature, particularly

in the critical operations of loading, unloading and refuelling. The

only sure way to prevent accident is to ensure that personnel are trained and

competent in the refuelling operation.

All fuel filling stations must be positioned

outside of the machinery spaces and so arranged that any overflow cannot come

into contact with any hot surface or spill overboard. The safety plan

for refuelling should include but not be limited to the following:

Training - all personnel are trained to understand the safety plan and operate the safety equipment in order to comply with safety management and port regulations.

Mooring – moor the vessel securely

allowing for tide and wash, secure fuel lines and pad where there are sharp

edges. Pipe bends

should be smooth, not leak and if necessary be earthed.

Isolating – no naked flames or smoking

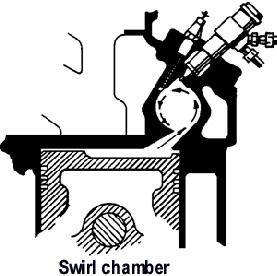

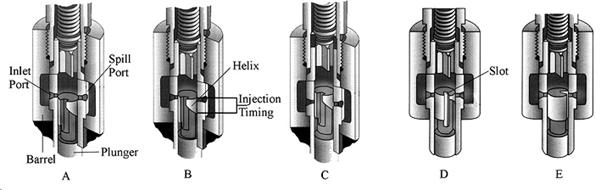

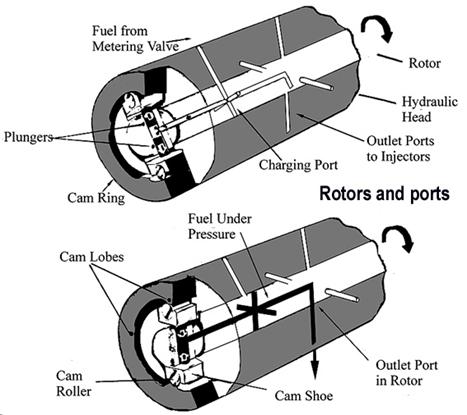

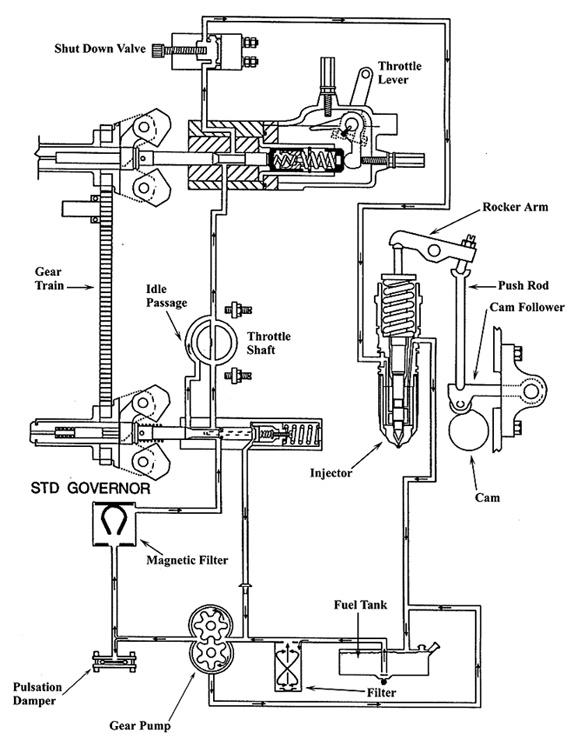

and have fire-fighting appliances in readiness. Plug